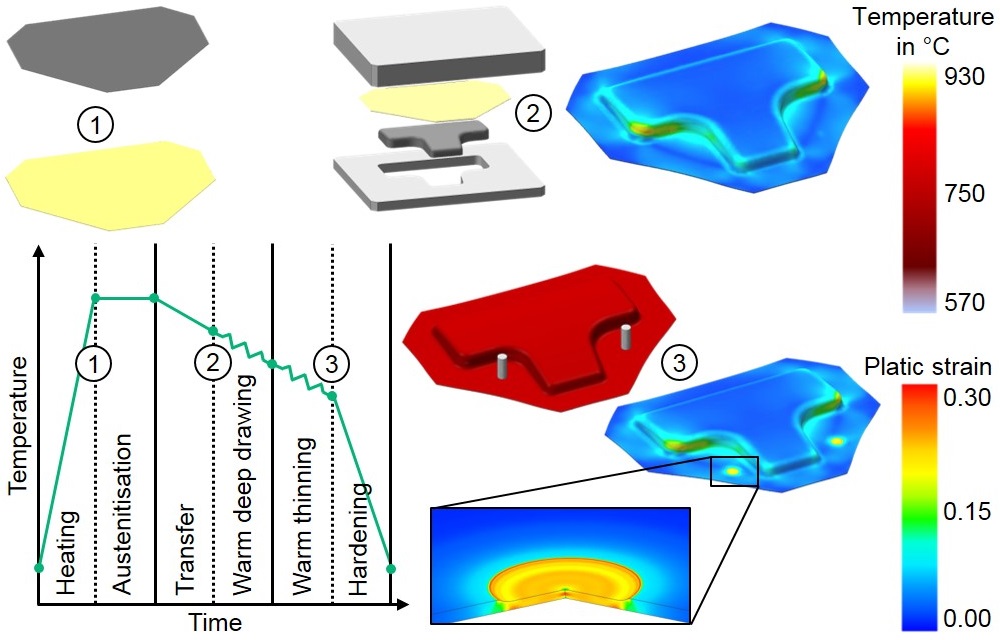

Hot-stamped structural parts are a key factor in automotive lightweight design, where 22MnB5 steel has become an established material in the production of safety-relevant car body parts. An improved reliability of joining technology would even widen the range of application of hot-stamped parts.

Up to now, ultra-high-performance car body parts are thermally joined to other parts by spot welding. Problems arise from uneven weld lense formation with improper bonding in multi-sheet joints. The applicability of mechanical joining processes like riveting is also limited due to the high strength and hardness of the hot-stamped parts.

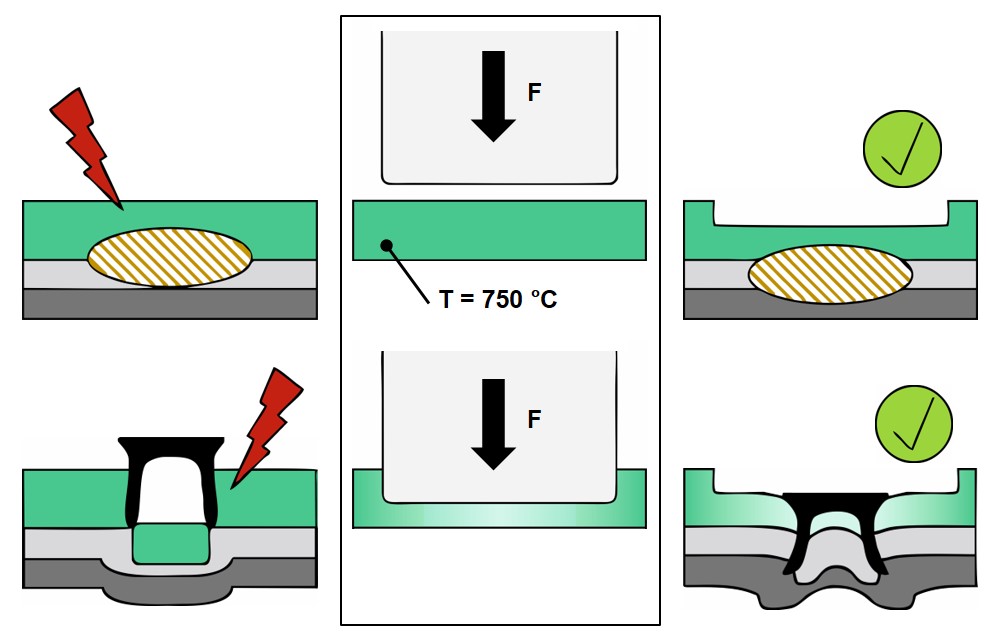

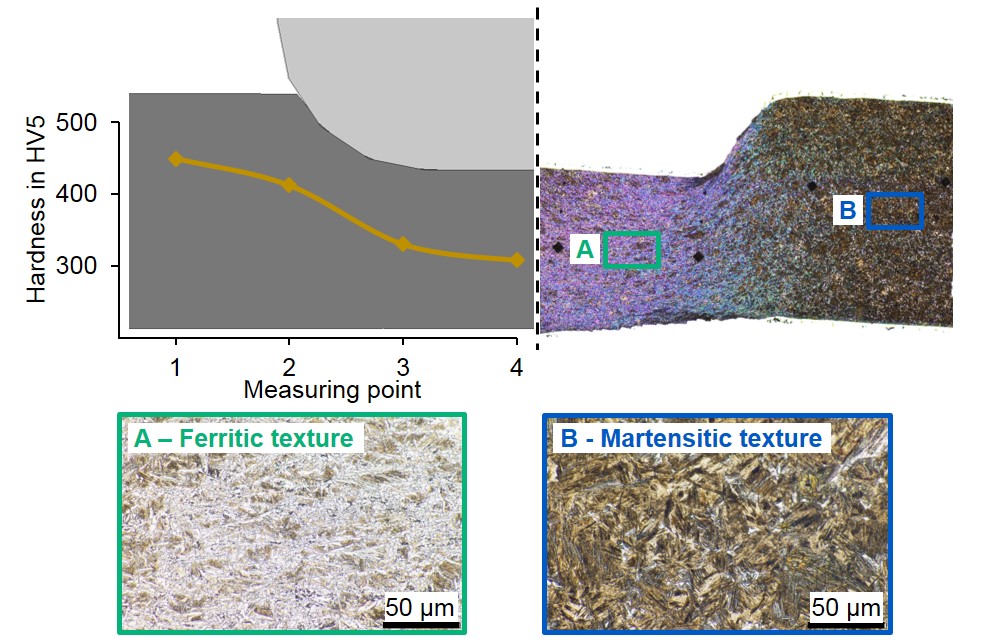

Researchers of the Institute of Forming Technology and Machines (IFUM) intend to improve the joinability of hot-stamped parts by local thinning and softening of the austenitised material. The result: improved thermal as well as mechanical joining techniques.