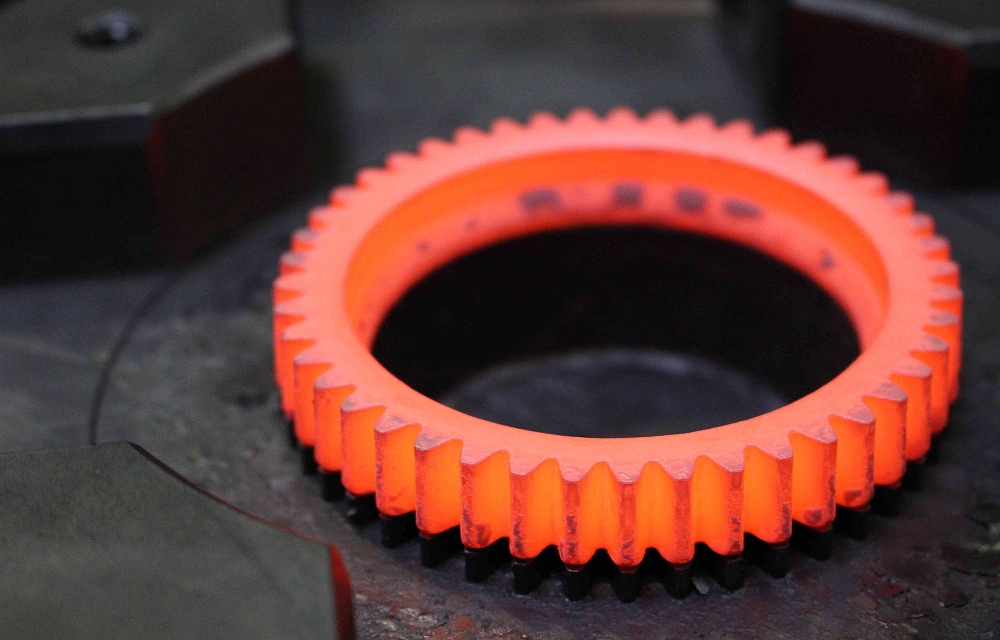

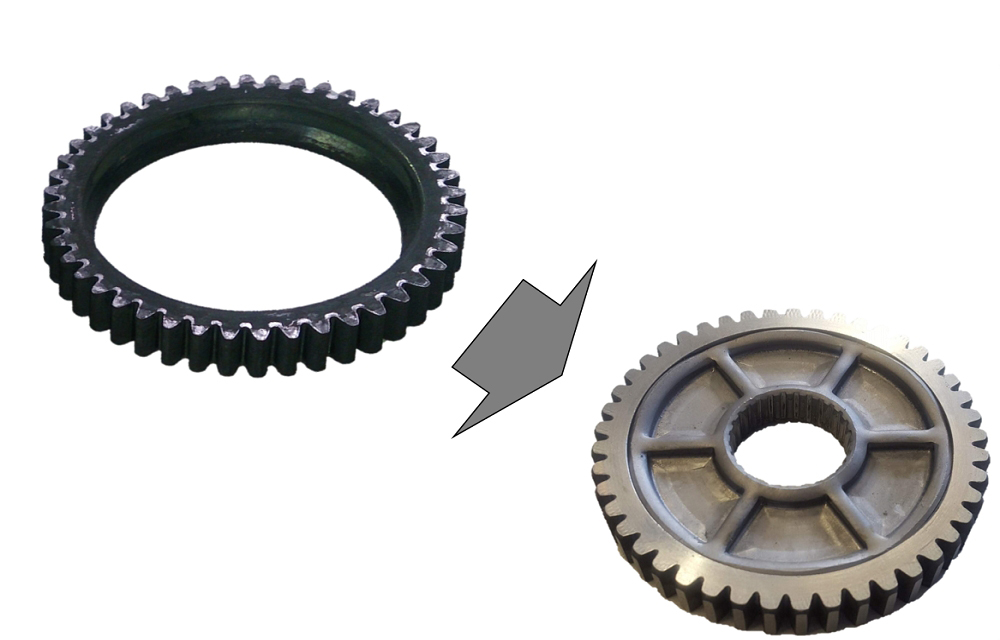

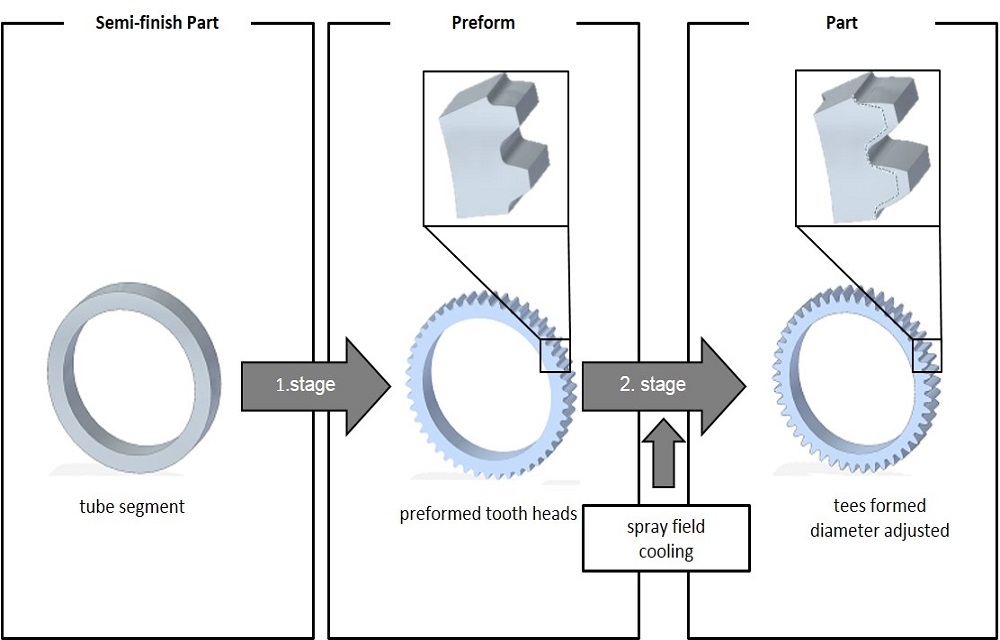

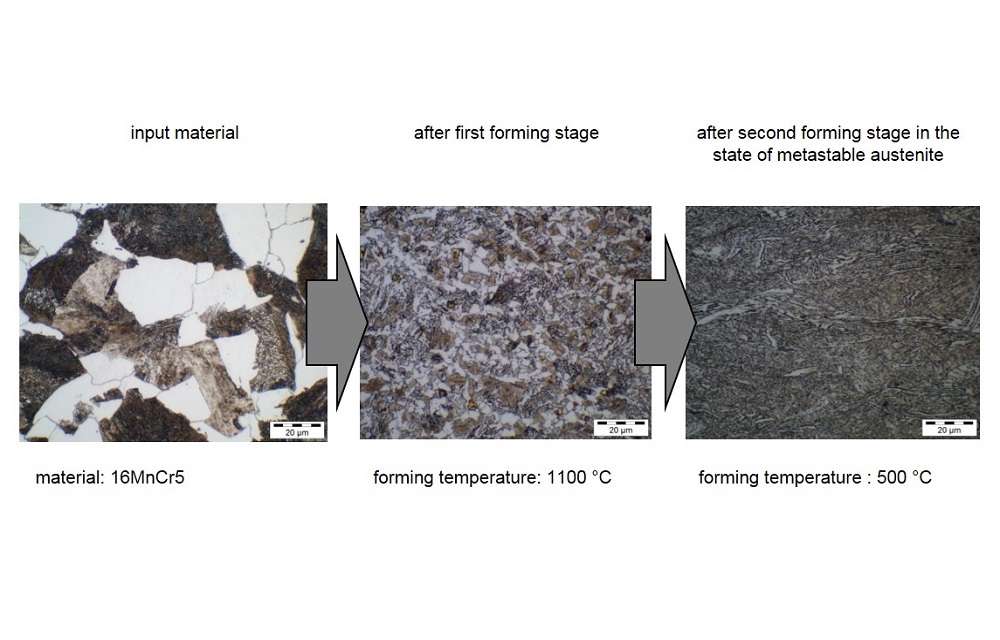

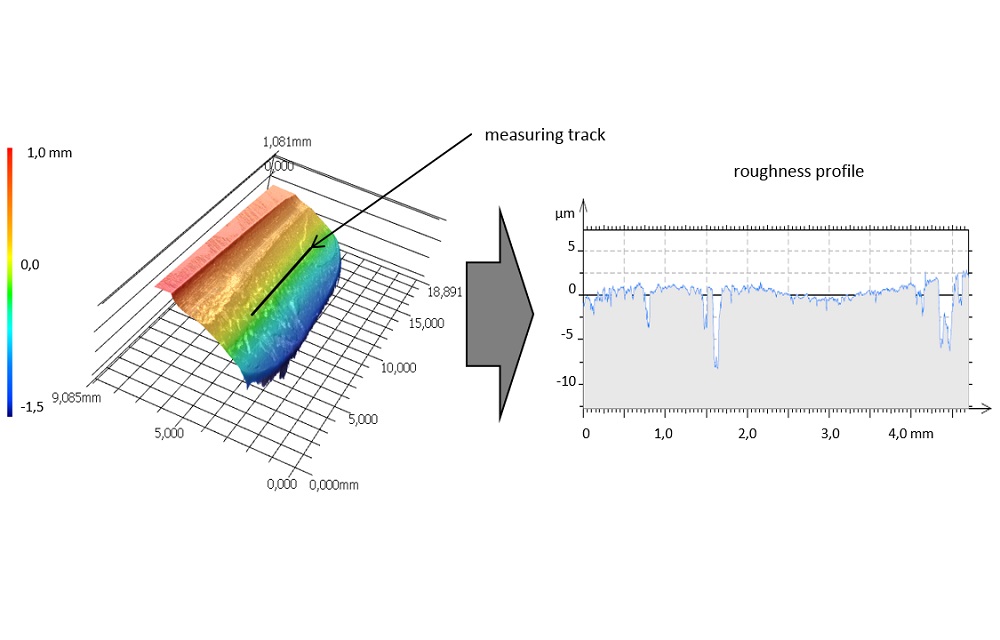

The central demonstrator developed in the joint research project "Lightweight Forging" is a gear wheel in multi-component design with optimized weight and efficiency. IFUM’s contribution is a thin-walled gear rim produced using multi-stage precision forging with thermomechanical process control. Thanks to a second forming stage at reduced temperature, the grain size of the case-hardened steel used can be reduced significantly. In addition, the second forming stage serves for component calibration in order to improve component accuracy and surface characteristics.

Research results prove that a fine-grained structure increases the strength and resistance of forged parts, thus making components more robust and less prone to failure. This and the multi-component design make hybrid gear wheels a lot lighter than previous versions. Consequently, vehicles have a lighter weight and an improved energy efficiency. Moreover, the production process is more resource-efficient, because less postprocessing is needed due to an improved contour accuracy and average roughness value.