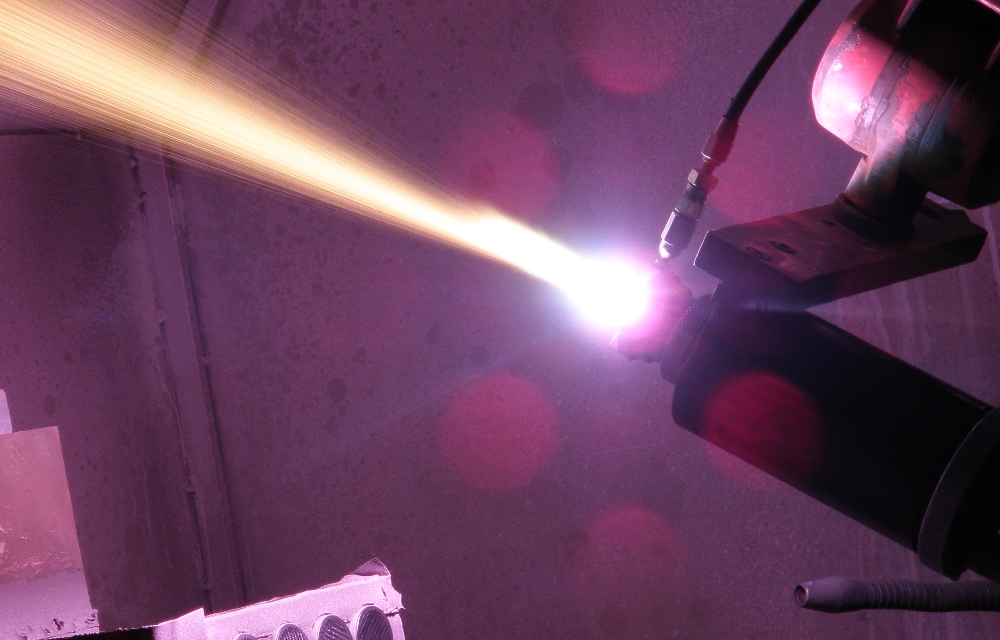

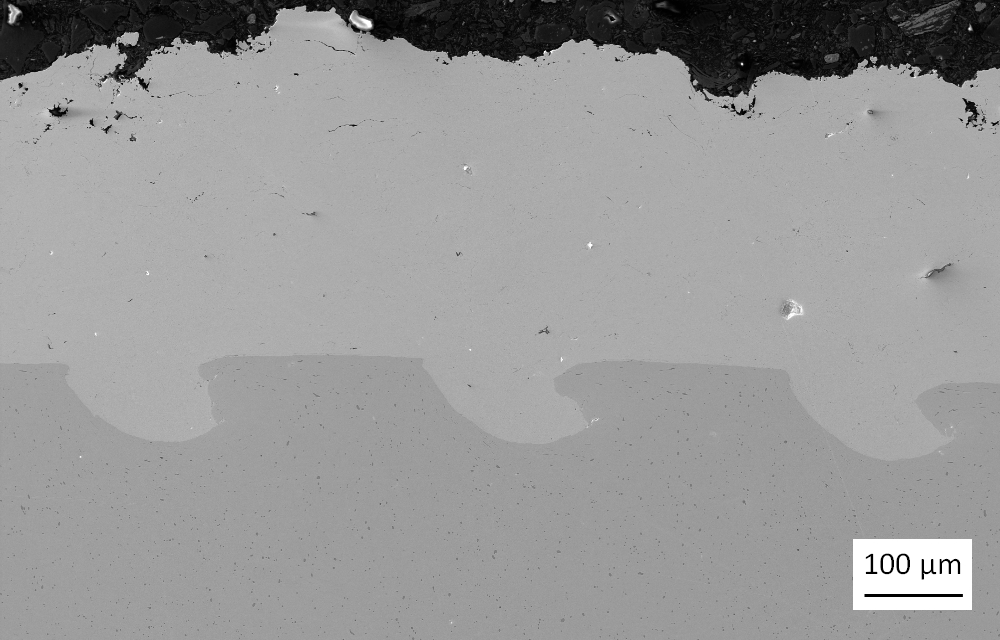

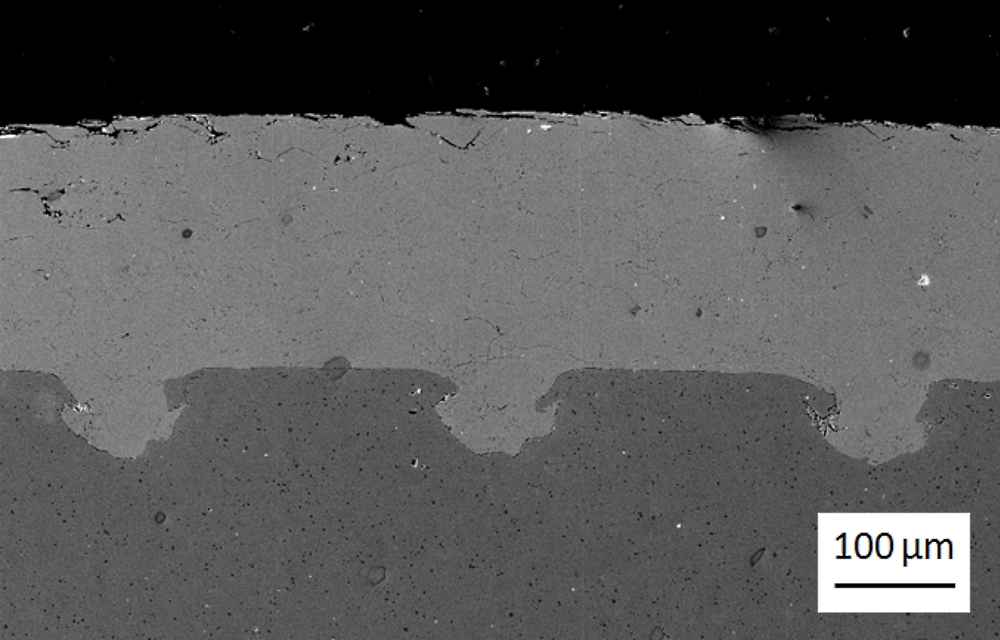

Scientists from the Institute of Materials Science (IW) and the Institute of Machining Technology (ISF) are designing novel surface structures which can reach the adhesive tensile strength required for thermally sprayed coatings without the need of a blasting process. For this purpose, a wave structure is applied to the surface of a steel shaft using a knurl milling process. Since the knurled wave structure alone cannot guarantee the required bonding quality, a rolling process is used afterwards to apply undercuts at the surface, thus improving the mechanical bonding of the coatings sprayed onto the substrate. Moreover, the spraying parameters and the post-treatments for the sprayed coatings are adapted to the new challenge.