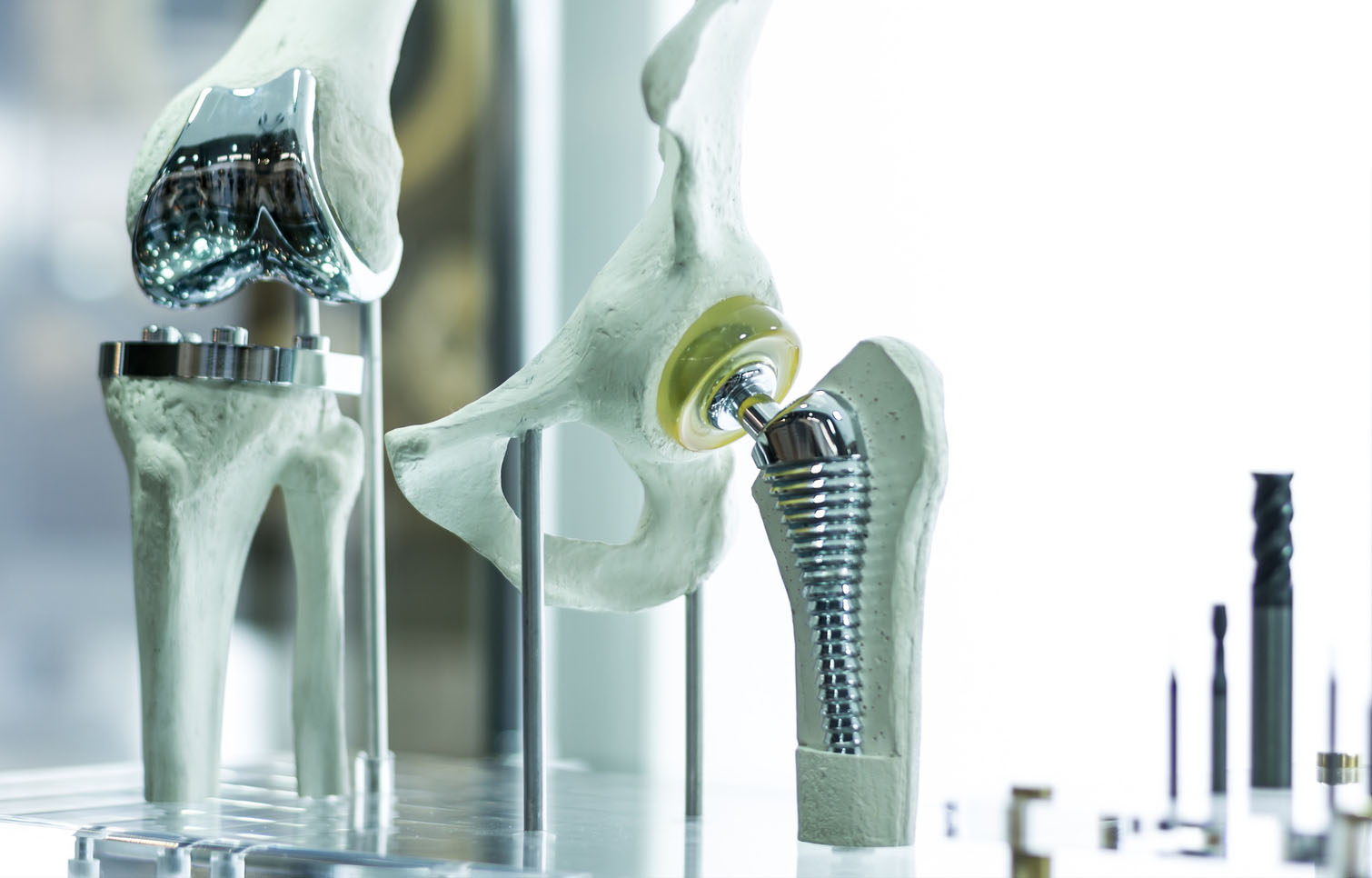

Arthrosis in hip and knee joints belongs to the most common diseases in industrialized countries. However, helping joint protheses often last no longer than 15 years, because microscopically small abrasive particles may cause inflammations or rejection reactions. Therefore, researchers of the Institute of Materials Science (IW), the Institute of Measurement and Automatic Control (IMR) and the Institute for Multiphase Processes (IMP) have developed a coating system that actively lubricates the friction surface and thus increases the durability of implants.

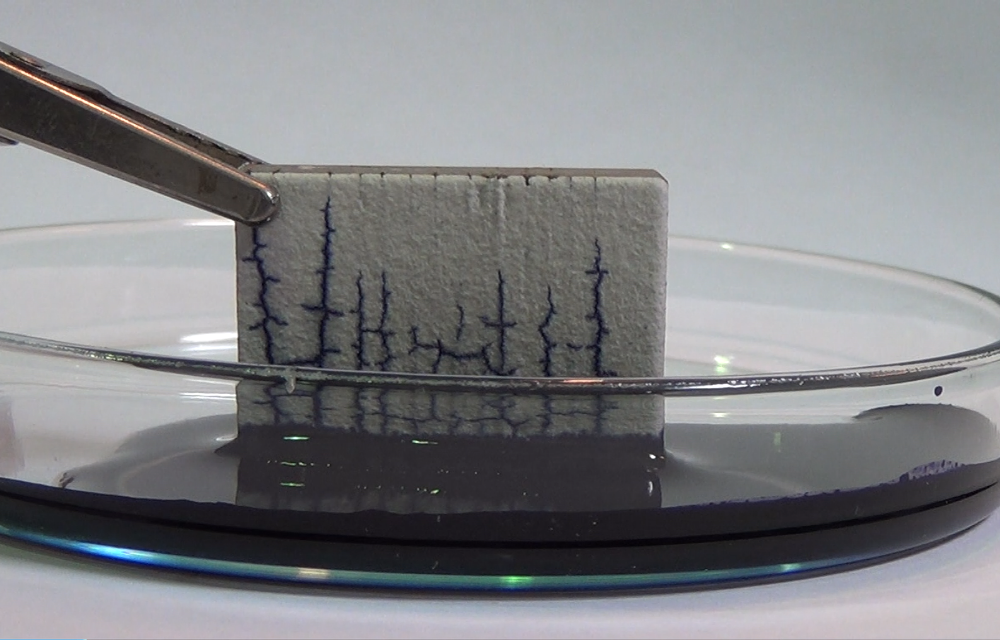

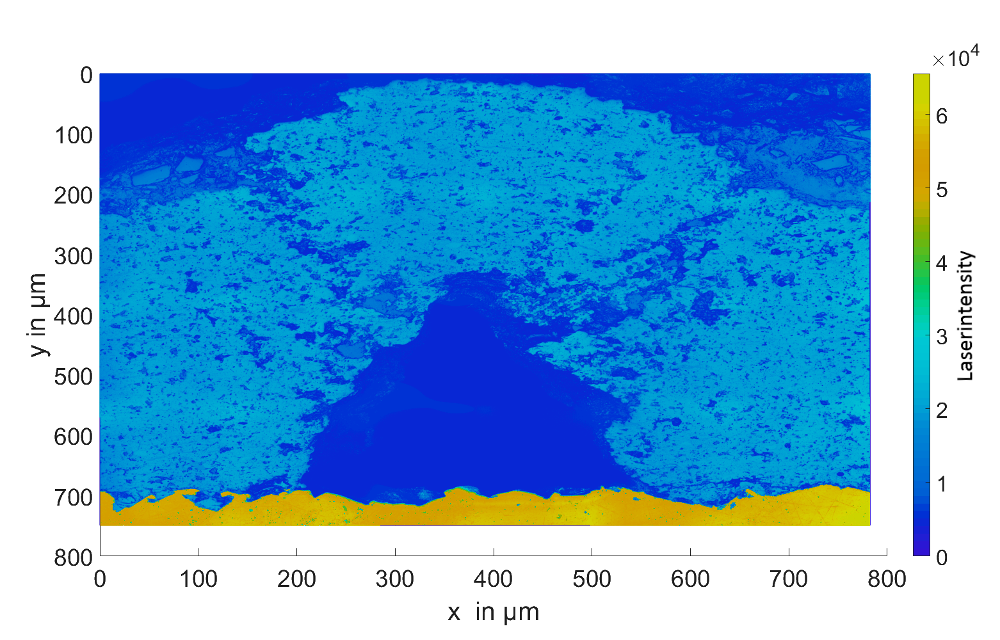

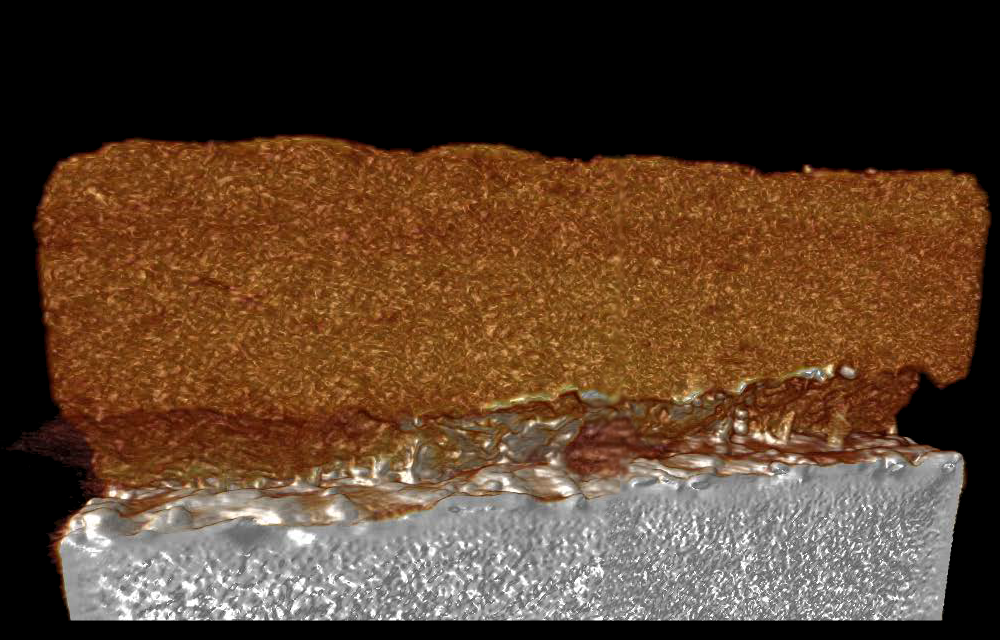

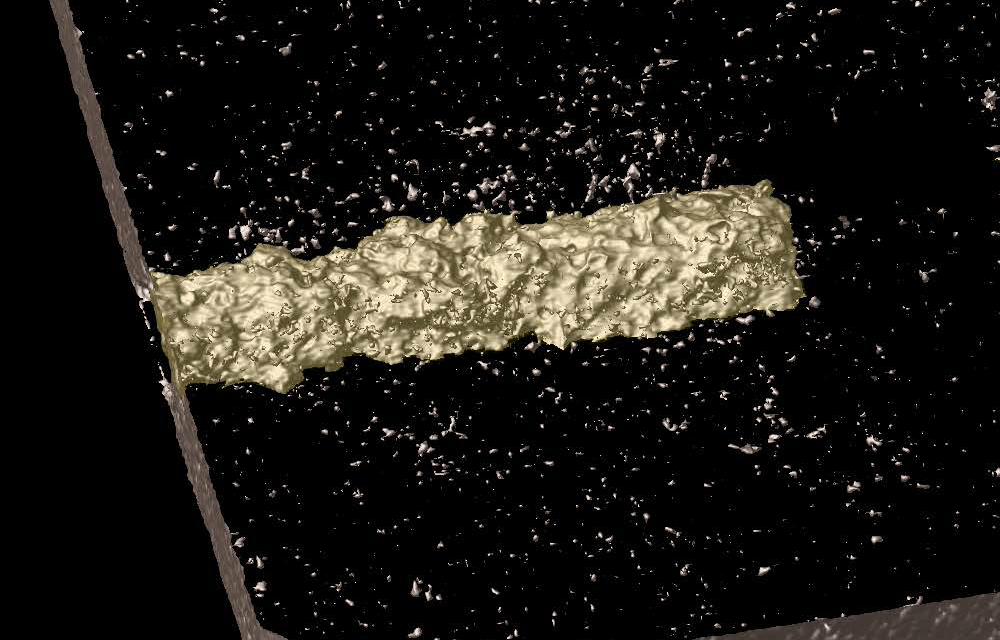

The wear-resistant ceramic coating is designed as a porous texture, allowing the synovial fluid to pass into the lubrification gap. Moreover, a capillary system is integrated into the ceramic coating that allows for an optimum distribution of the human synovial fluid. This is done by applying magnesium strips to the substrate that are etched away after the ceramic coating process.