In conventional tempering processes, steel is first heated to approx. 1000°C and then quickly cooled down to room temperature. This process changes the structural texture of steel: Austenite is transformed into martensite, making the material harder but also more brittle. Further heat treatments reinforce the material’s toughness without suffering a significant loss of hardness.

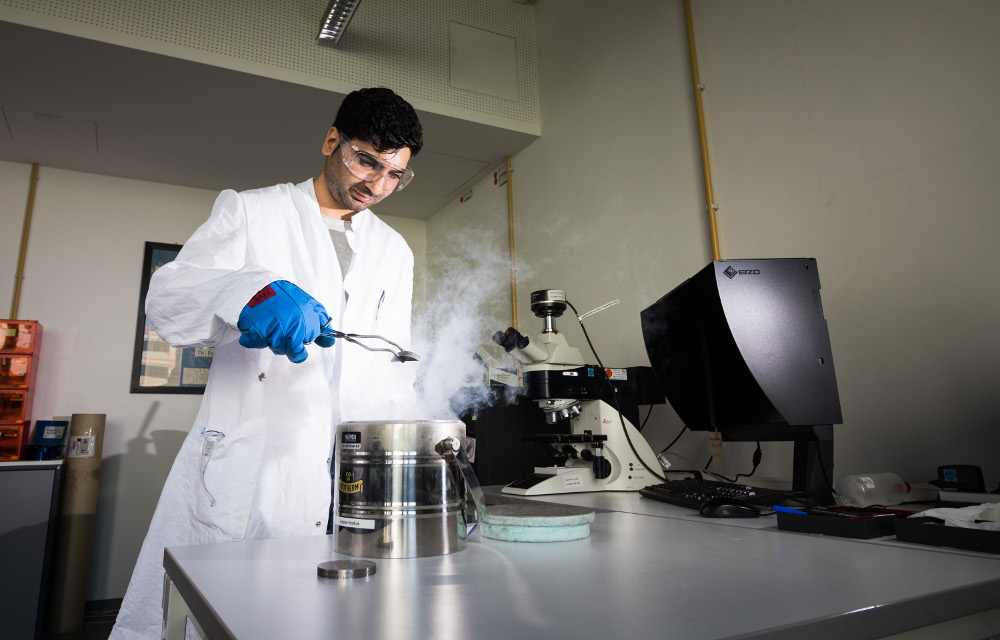

To enhance the lifetime of tools and components even more, researchers at the Institute of Materials Science (IW) of Leibniz Universität Hannover are investigating the so-called cryogenic treatment, where tool steels are deep-frozen to temperatures down to at least -120°C and -196°C at the most – using liquid nitrogen.

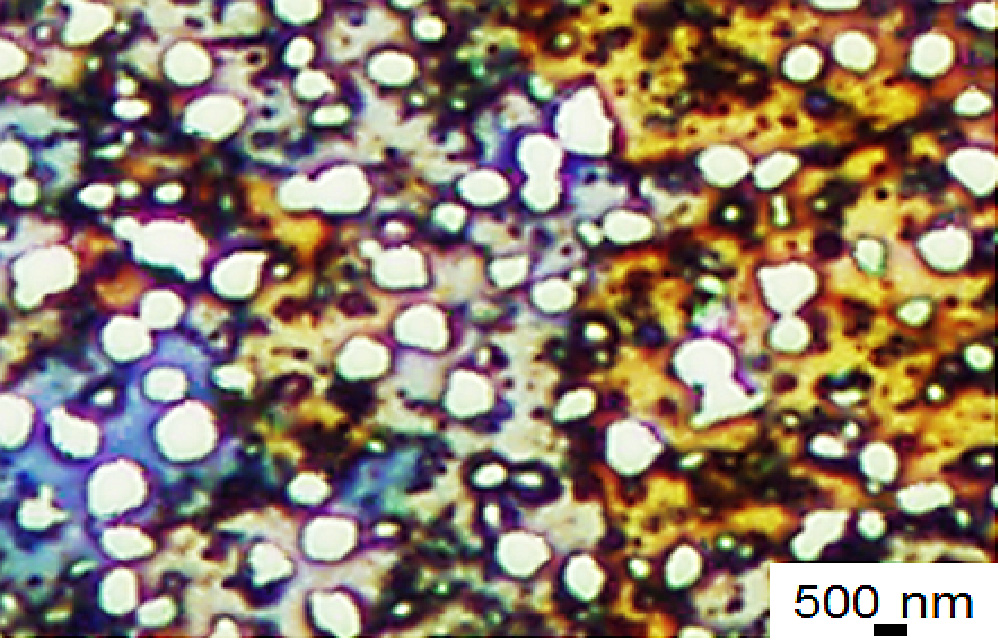

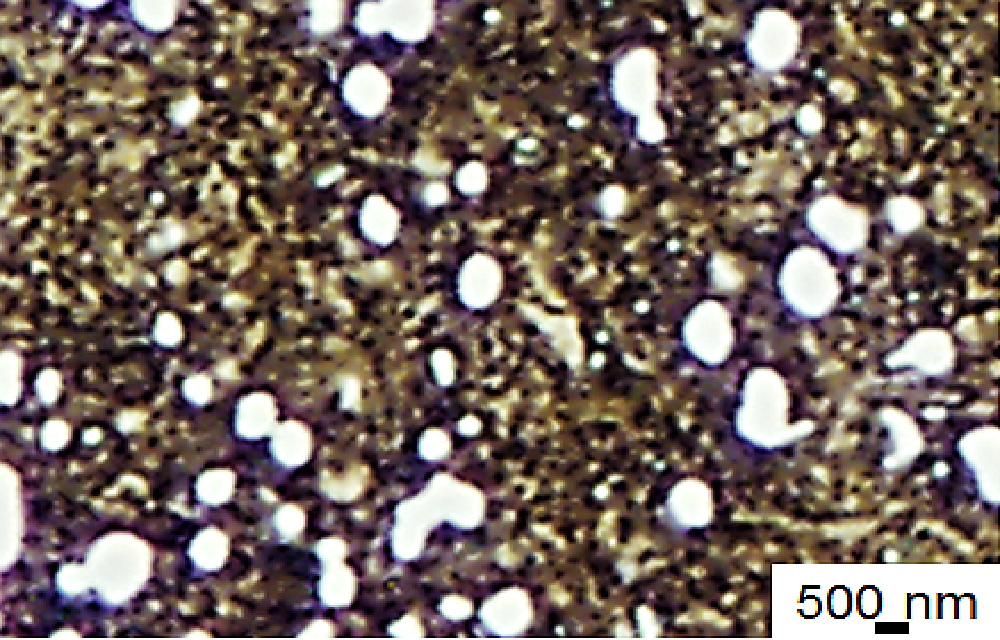

Among others, the aim of cryogenic treatment is a homogeneous distribution of carbides. Carbides are hard metal-carbon composites in the steel microstructure with an uneven distribution in the raw material (see Fig. 2). After heat treatment, the carbides are finely distributed, enhancing the degree of homogeneity and thus the strength and wear resistance of steel (see Fig. 3).