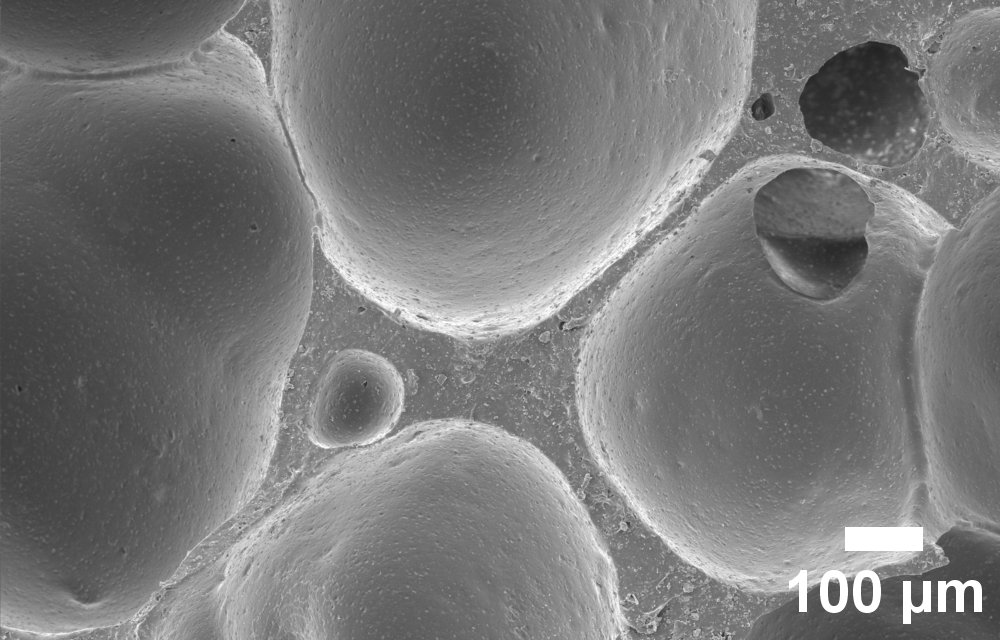

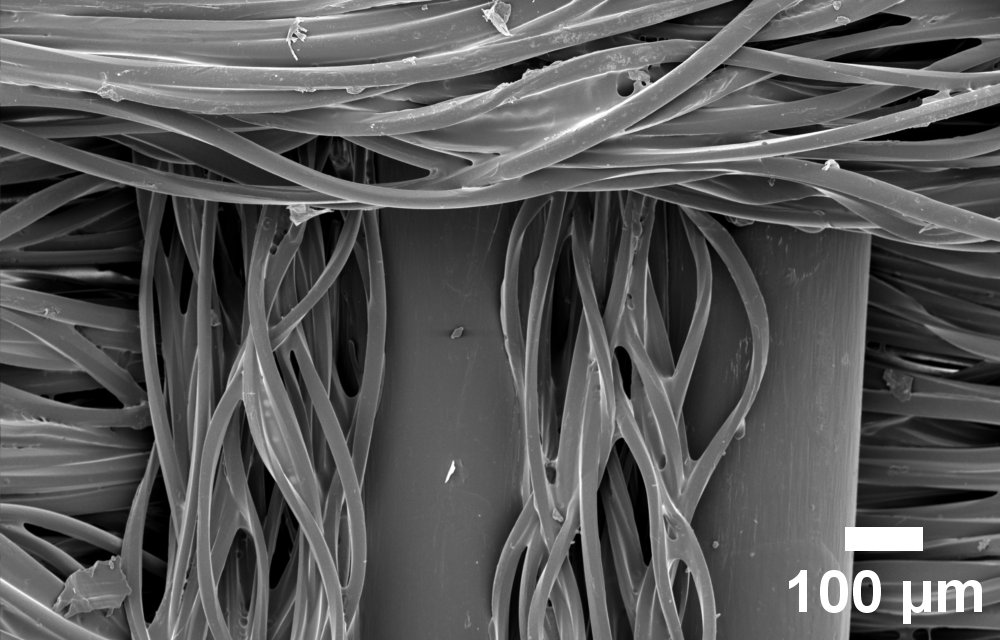

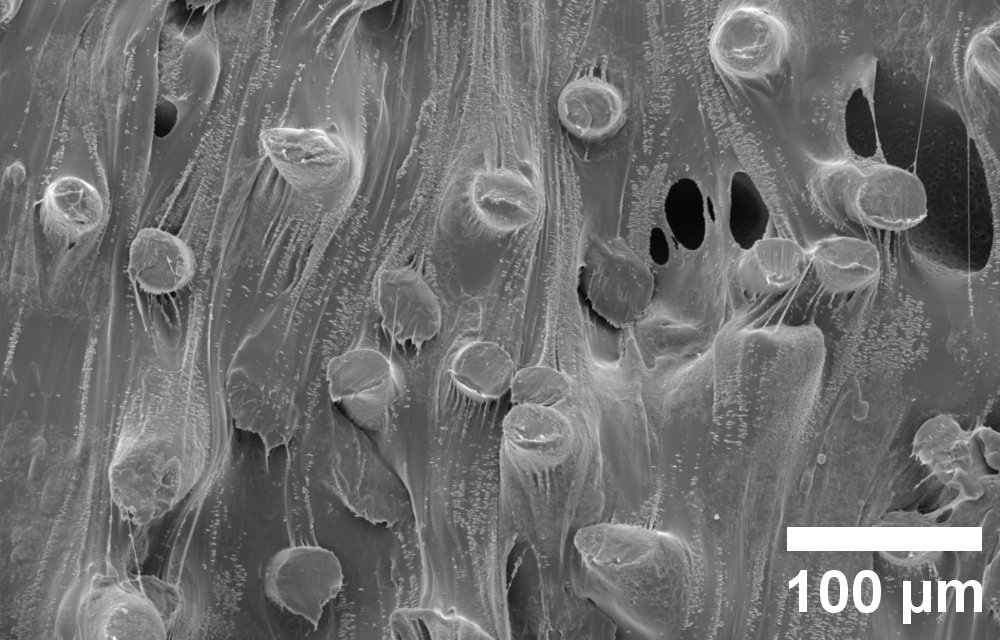

In SEM examinations, a finely focused electron beam scans samples line by line, similar to the image formation in old tube TV sets. Interaction of the electron beam with the sample produces various signals that can be recorded by detectors and converted into an image. This allows details much smaller than 1 micrometer to be displayed. For comparison, cling film, such as that used in households, has a thickness of approximately 10 micrometers. “SEM examinations allow us to analyze the material structure of plastic samples or, for example, to characterize aging and failure behavior,” explains Dr. Florian Bittner, head of materials testing at IKK.

Improved material and recycling concepts

This enables the team to precisely analyze the structure of complex material composites, such as those used in the packaging sector, in order to develop new recycling strategies. Currently, these materials are difficult to recycle. Therefore, they usually end up in the batch of energy recovery in sorting plants and are incinerated after one-time use.

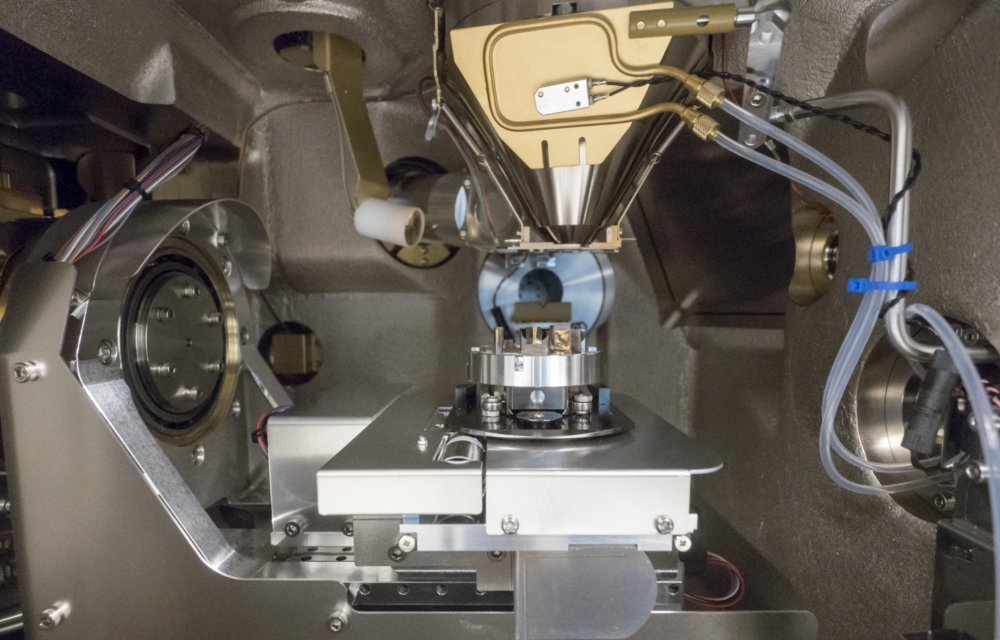

The new analytical scanning electron microscope (SEM) is complemented by a cryo-argon ion polishing system for sample preparation. This uses an argon ion beam to create a cross section in the sample materials to expose and evaluate the internal structure. Compared to other methods, this is very gentle on the material and is therefore of great advantage, especially for plastics. For example, it can be used to examine partially biodegraded plastic samples in order to follow the processes of material degradation inside the sample. Understanding these degradation processes is especially important when dealing with materials that inevitably remain on land and in the sea in parts or as a whole, such as agricultural films or fishing nets. “The more we know about the degradation behavior of these products, the better we will be able to develop alternatives that have less negative impact on the environment as they remain there,” Bittner is certain.

The structure and composition of material composites such as multilayer films or mixed textiles can also be studied in detail in this way, thus providing crucial knowledge for new recycling approaches.

The “cryo” in the name of the SEM, which refers to the extremely low processing temperatures, is currently less relevant for the research activities at IKK – but all the more so for the Institut für Mehrphasenprozesse (IMP), with which it is jointly operated. There it is used, among other things, in the research field of cryogenics.

Laboratory equipment for sample preparation

The laboratory is also equipped with a microtome, a type of cutting device that separates thin layers of samples for investigations. A precision cut-off machine can be used to cut smaller samples from voluminous ones. A sputter coater is used to coat samples with very thin layers of metal, for example gold. This makes the samples electrically conductive, which facilitates imaging in the SEM. This is particularly relevant for plastic samples, as these are usually non-conductive.

The new equipment will enable the IKK in the future to analyze the microstructure of the polymer materials considered in the various projects, in order to better understand interactions and to incorporate them into material development.