The demands on optical elements are constantly increasing. The production of an individual and highly functional optical element is costly and complex according to the current state of the art. Multi-stage production is often done by hand, which is associated with high costs. For this reason, the scientists in the Cluster of Excellence PhoenixD want to redefine the design and manufacture of precision optics.

Glass components from the 3D printer

Additive manufacturing – also known as 3D printing – represents an alternative to conventional methods in the manufacture of precision optics, since it offers high flexibility and design freedom. Individual components can also be manufactured comparatively quickly using additive manufacturing processes. Glass is the classic material for optical elements – because in contrast to metals and polymers, it offers several advantages, including thermal stability, chemical resistance and high optical light conductivity.

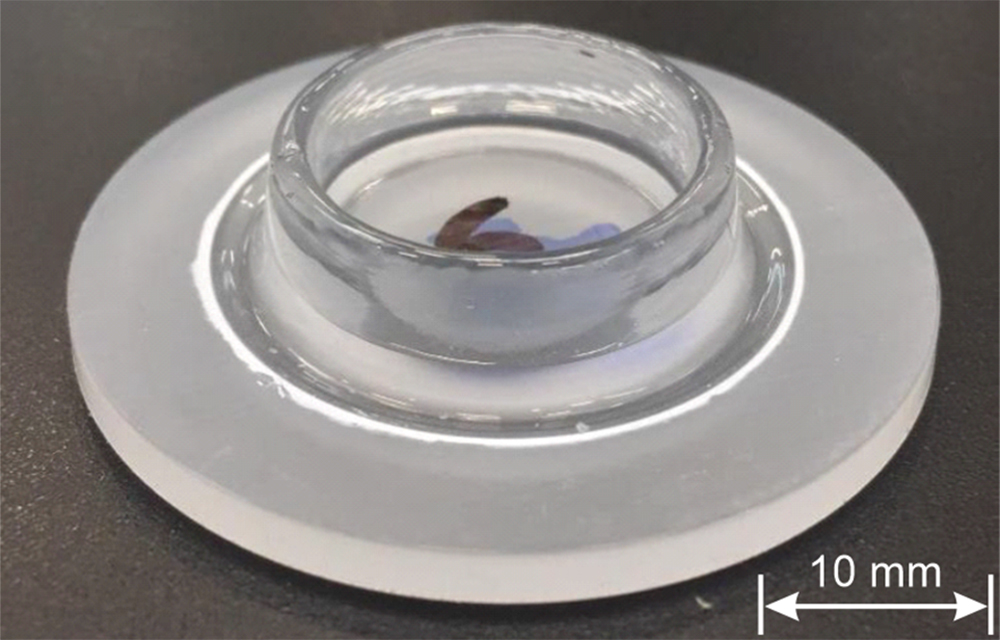

But can glass be manufactured additive? According to the current state of technology, the possibilities are limited. In the Cluster of Excellence PhoenixD, scientists from the Laser Zentrum Hannover e.V. (LZH) and the Institute of Production Engineering and Machine Tools (IFW) are therefore researching on laser glass deposition (LGD) as a new manufacturing method.

Since laser glass deposition is a very complex process, process control variables such as laser power, printing speed or feed rate of the glass fiber are usually determined by means of adjustment tests. This increases the manufacturing costs for the production of components in small batches and makes them uneconomical. In the future, simulation models are to be used to reduce the experimental effort.

Simulation-based process planning

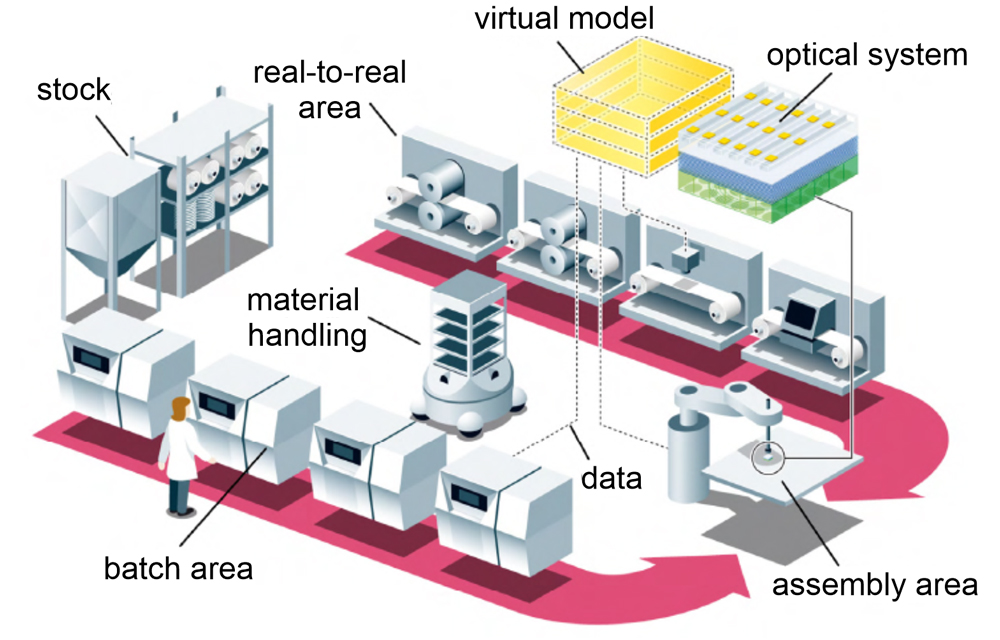

In the cluster of excellence PhoenixD, the IFW is researching process planning for additive manufacturing using simulations. The aim is to virtually re-build the production line and thus select optimal process parameters. In addition, the additive-manufactured product requires further processing steps in order to obtain desired component properties and functionalities. Simulations are used to check if the component can be manufactured with the respective process control variables according to the requirements and if the control variables must be optimized. This saves time and money during post-processing.

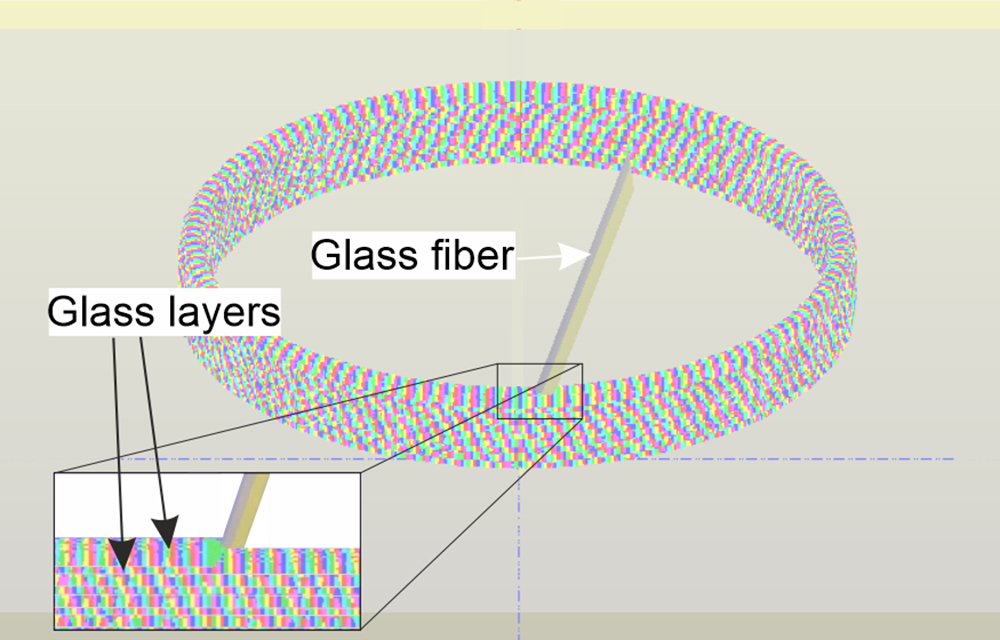

The IFW CutS program developed at the IFW is a simulation platform for different machining production processes. Within the framework of PhoenixD, the IFW is extending the platform to include the simulation of additive manufacturing. The next goal of the IFW is to simulate the geometry of the additive manufactured glass layers according to the respective process parameters. For this purpose, scientists from IFW and LZH investigate the influence of process parameters on material properties and component geometry during laser glass deposition in order to gain a better understanding of the process behavior.