Hybrid semi-finished products can save material and costs in production if only those parts of a component are made from a high-priced material that is subject to high demands in later use, and therefore, for example, has to be particularly wear-resistant. The Collaborative Research Center SFB 1153 “Tailored Forming” is developing a novel process chain for the production of load-adapted hybrid solid components in which the semi-finished products are first joined and then formed. To this end, the LZH is conducting research on two laser-based processes.

Formable semi-finished products manufactured by US laser beam welding

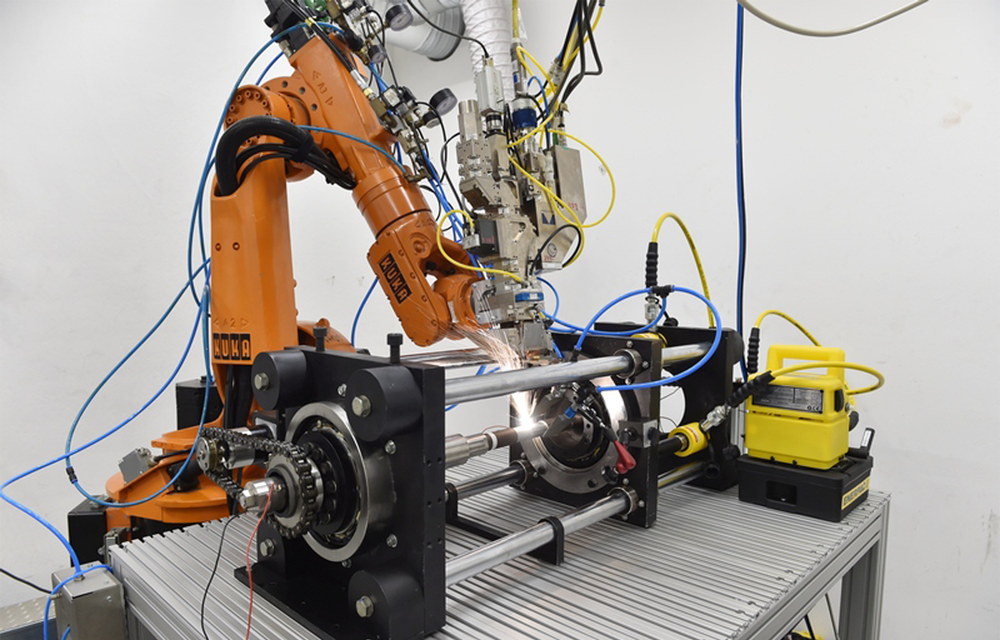

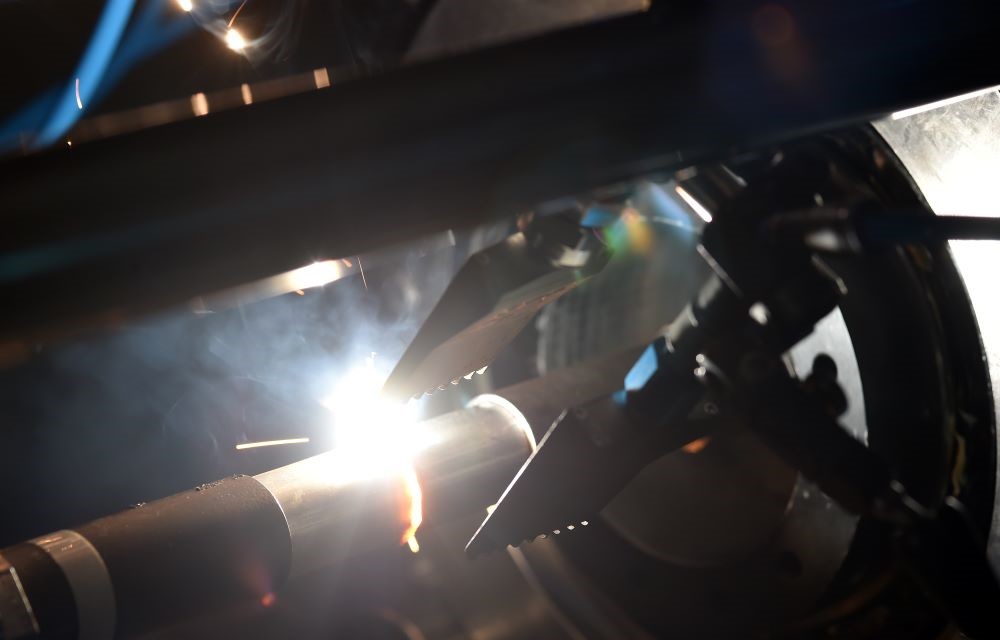

The Joining and Cutting of Metals Group was able to produce crack-free formable semi-finished products using an ultrasonic-assisted laser beam welding process. The scientists welded shafts made of various mixed compounds such as steel-steel or steel-nickel and developed corresponding processes. They focused on the question of how cracks can be avoided and which parameters in the welding process influence quality characteristics such as weld penetration depth or weld reinforcement.

In the third funding period of the Collaborative Research Center, the group wants to ensure greater process stability by modulating the laser power. The scientists also aim to develop process control to achieve repeatable, reliable quality in producing semi-finished products. In addition, mechanical stresses in the component are to be reduced by ultrasonic post-treatment.

Within the subproject “Ultrasound-assisted laser beam welding for the generation of formable mixed compounds”, the researchers worked closely with colleagues from the Institute of Dynamics and Vibrations (IDS), who were involved in generating the ultrasound and evaluating the measurement data.

Laser deposition welding takes local stress into account for components

The Machines and Controls Group is conducting research into novel components with local, load-adapted property profiles. To this end, the scientists have used laser hot-wire deposition welding to apply cost-intensive, high-strength material as a coating specifically to areas of the component that are subjected to high loads during operation. Exemplary applications are tooth flanks of gearwheels. In this way, high-quality and hard coatings could be applied, and the properties of the coating were specifically influenced by the material selection. The researchers have also succeeded in producing coatings from the rolling bearing steel 100Cr6, which is classified as non-weldable due to its high carbon content.

In the next step, the group would like to develop process monitoring for quality assurance in deposition welding. For this purpose, the secondary radiation generated in the welding process is to be measured with special sensor technology and analyzed with machine learning methods to be able to derive a prediction of the coating properties. The goal: non-destructive quality control of the coatings in the process.

In addition to laser deposition welding, the Institute of Materials Science (IW) investigated plasma powder deposition welding in the subproject “Spatial adaption of material properties of forming parts using surfacing techniques to produce graded hybrid components”.

About the Collaborative Research Center

The work of the LZH is part of the Collaborative Research Center SFB 1153 “Process chain for the production of hybrid high-performance components through tailored forming”, in which experts from nine institutes of the Faculty of Mechanical Engineering at Leibniz University Hannover, from the LZH and the Institute for Integrated Production Hannover IPH are working on developing new process chains for the production of hybrid components.

The SFB started its work in July 2015. The third funding period runs for 4 years and starts in July 2023. It is funded by the German Research Foundation under the funding code 252662854.

More information about the Collaborative Research Center 1153 is available on the website of Leibniz University Hannover.