Under the direction of Prof. Dr.-Ing. Hans Jürgen Maier and Apl. Prof. Dr.-Ing. habil. Kai Möhwald, FORTIS and DGM invite interested engineers and technicians from the development, construction and production sector to take part in the workshop "Modern Coating Methods" on 6 and 7 November 2018 at the Parkhotel Witten. Participants learn how to estimate the potential for surface protection layers and coating methods in their field of work with the objective to make coating technology an integral part in development, construction and production.

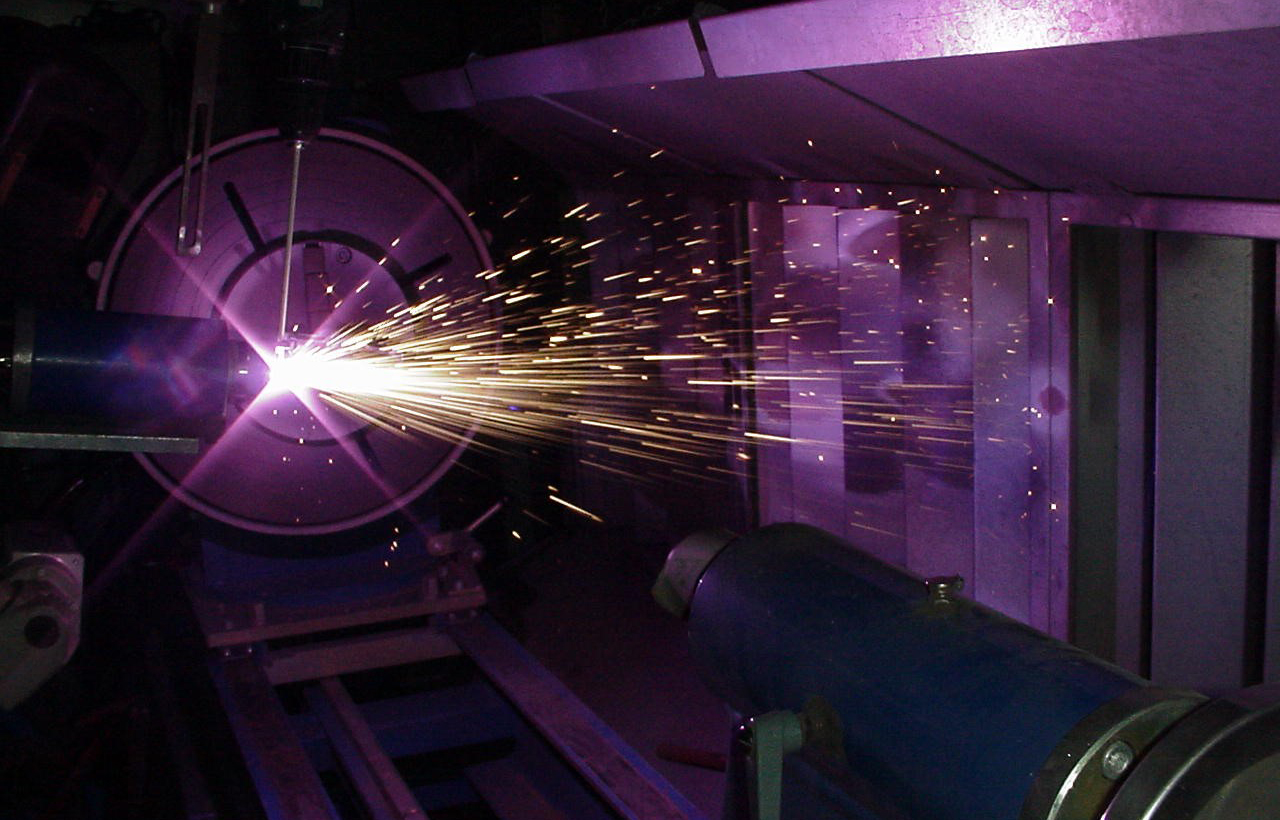

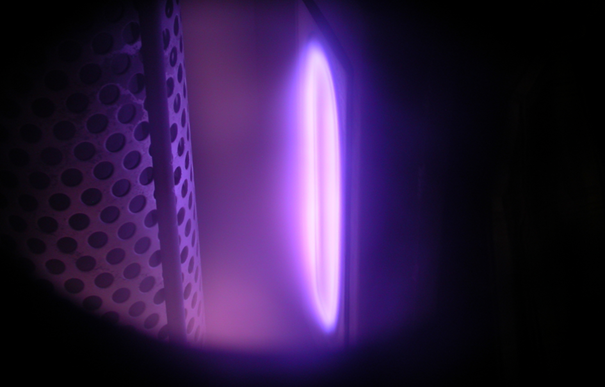

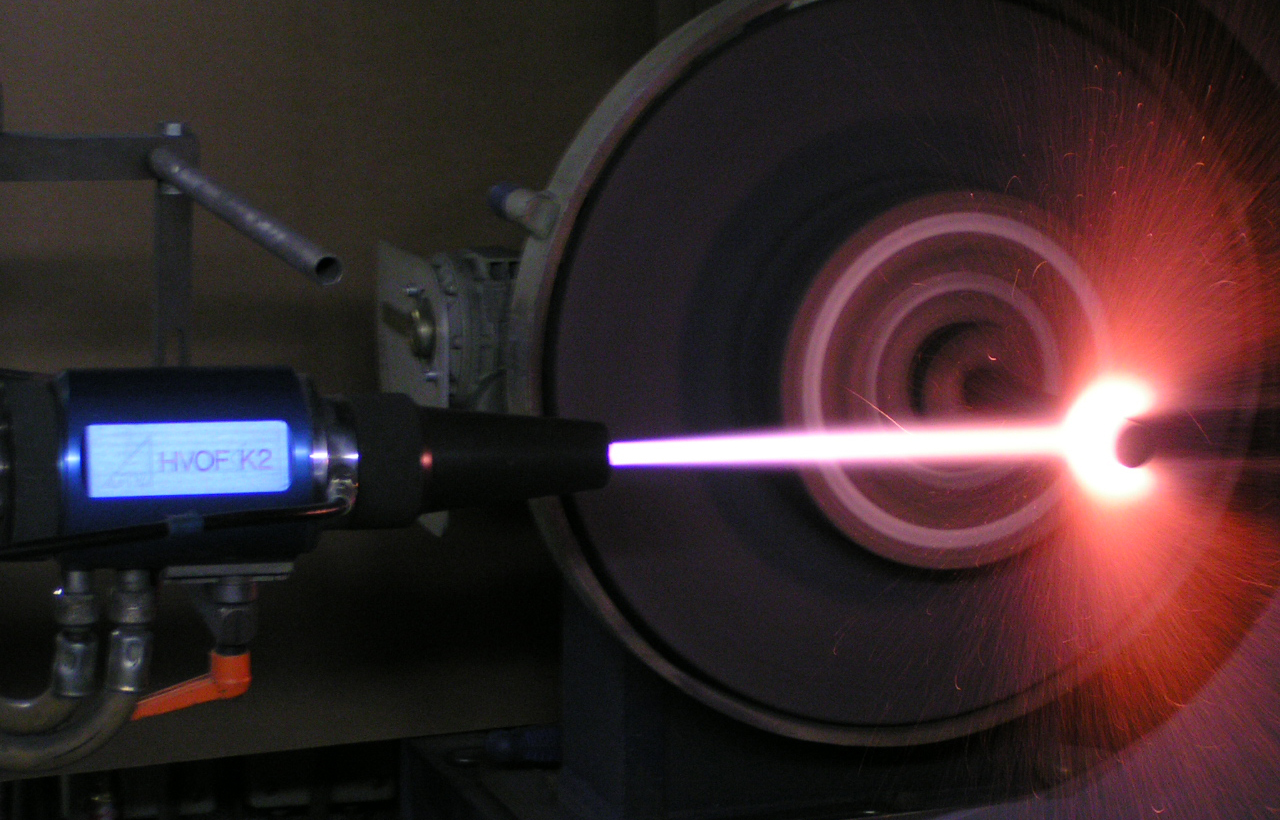

As part of the workshop, FORTIS presents coating systems and processes with the scientific focus on coating, surface and soldering technology. These technologies are investigated in various fundamental and application-oriented, publicly funded research projects as well as within the scope of development services for the industrial sector.