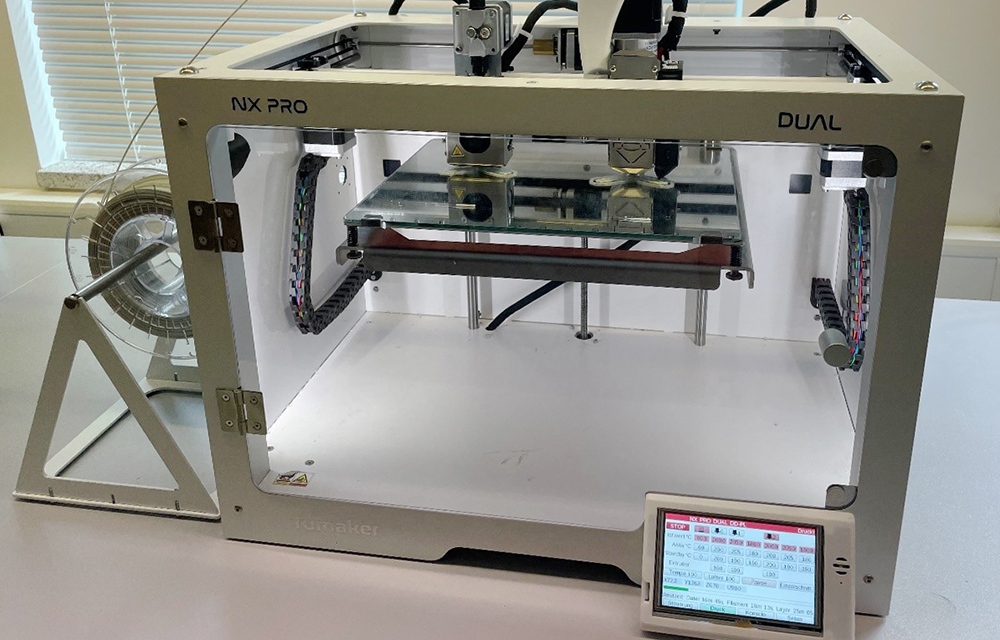

There is a wide variety of 3D printers for producing plastic components using the Fused Filament Fabrication (FFF). As a rule, the printers work with filament in this process. The new 3D printer at IPH, a TUMAKER NX PRO DUAL, on the other hand, can process both filament and plastic granulate. For this purpose, the printer is equipped with two different print heads, which can also move independently of each other on one axis. This independence enables mirror printing, in which two identical components are produced simultaneously. For a high degree of variability, two additional print heads are also provided, which allow the printer to be converted so that it can produce two components from filament or two components from granulate.

3D printing with granules

Printing with plastic granules offers several advantages. First, there is a wide variety of materials that is no longer limited to filaments available on the market, but also includes newly developed, certified and approved materials made from granules. This means that materials from injection molding can also be processed. It also simplifies the use of recycled plastic.

More efficient recycling

The manufacturing process of recycled filament usually begins with shredding plastic parts into flakes. These are then dried and melted in an extruder and extruded into new filament. In the future, the new printer is expected to bypass the filament manufacturing step in the recycling process, increasing the efficiency of the process. The shredded flakes will be fed directly into the printer and printed. To this end, IPH is planning some modifications, such as a finer ventilation grille on the printer, since currently only granules with a diameter of at least 3 mm can be processed. In the end, it should thus be possible to compare components made from recycled filament with components made from directly printed flakes.

3D printing at IPH

The new 3D printer expands the technical equipment of the 3D printing laboratory at IPH. Among other things, the printer will be used in the „Niedersachsen ADDITIV“ project and should also enable industrial projects at IPH in the future, which include printing new materials, for example.