There is a great market demand for individual products. However, customers are not ready to pay for them. One approach to solve this conflict is automated additive manufacturing – also known as 3D printing.

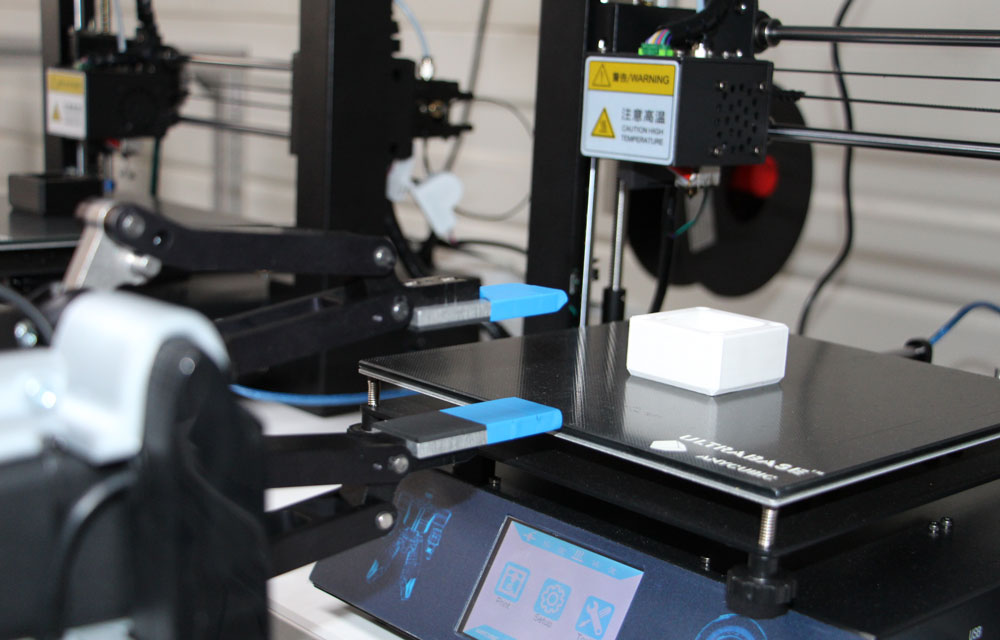

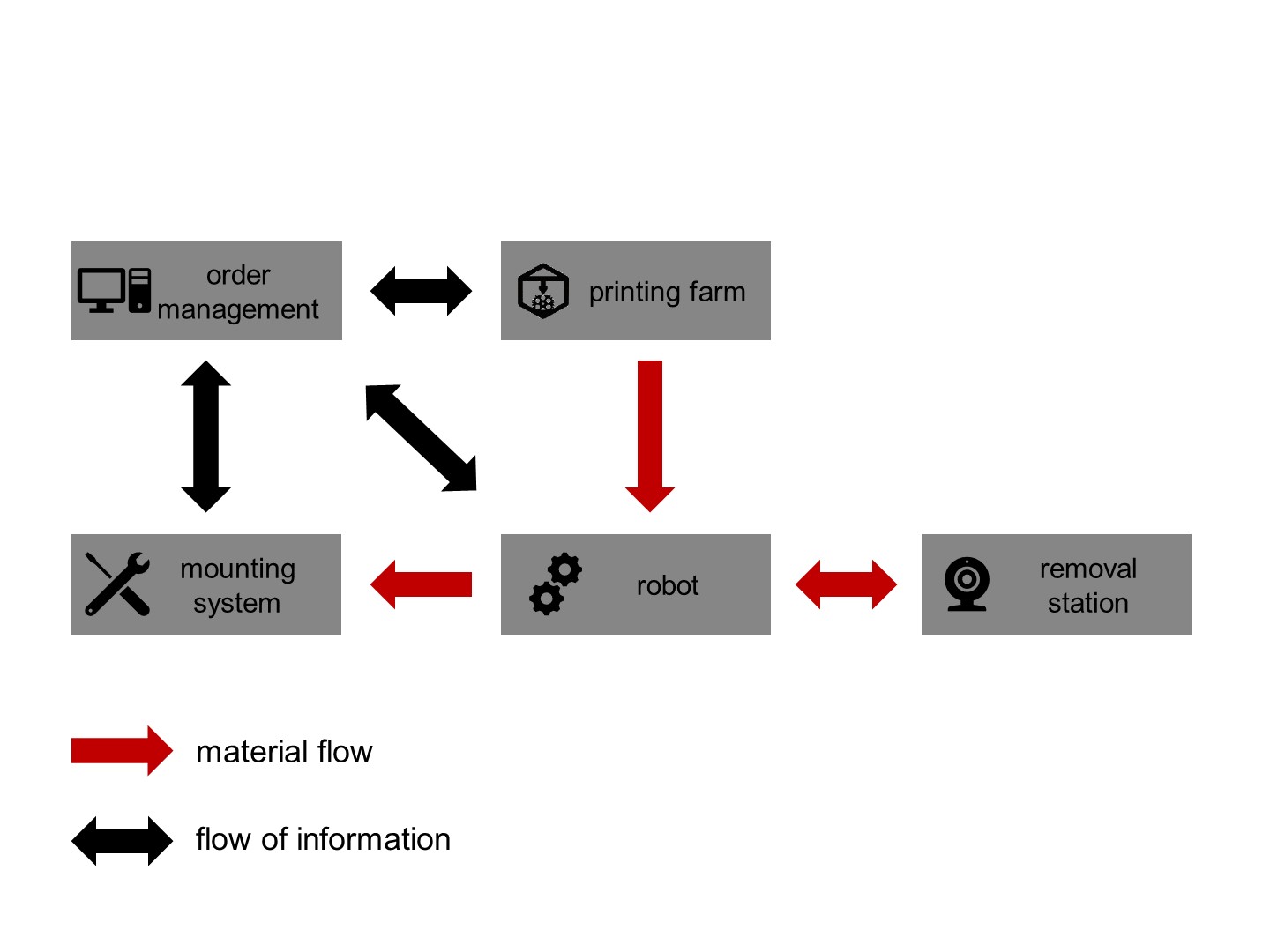

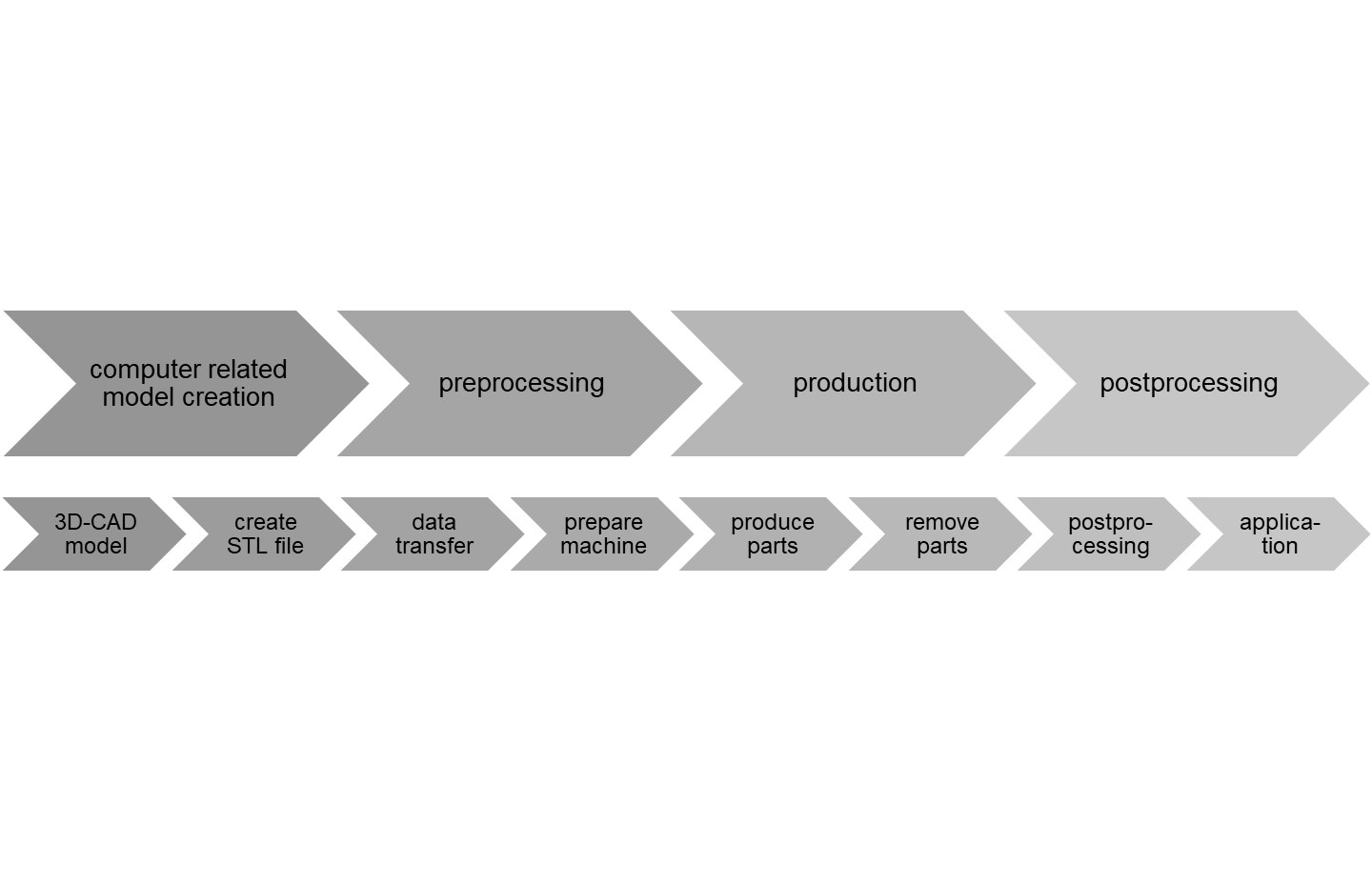

Within the scope of a research project, IPH researchers have been designing a demonstrator process chain linking several additive extrusion systems for the production of plastic parts with downstream mounting stations automatically. The core of the overall concept is a printer farm: a rack with several 3D printers. By using several smaller systems, the output of a large production plant can be achieved with considerably less investment costs. To evaluate the results, IPH produces sample parts, which are then processed by mounting stations.