The mass use of plastics leads to considerable environmental problems. A large proportion of plastic products are only used for a short time or on a one-off basis, and plastic waste produced ends up in the oceans, for example, and is ingested by marine organisms via food.

IPH wants to recycle plastics

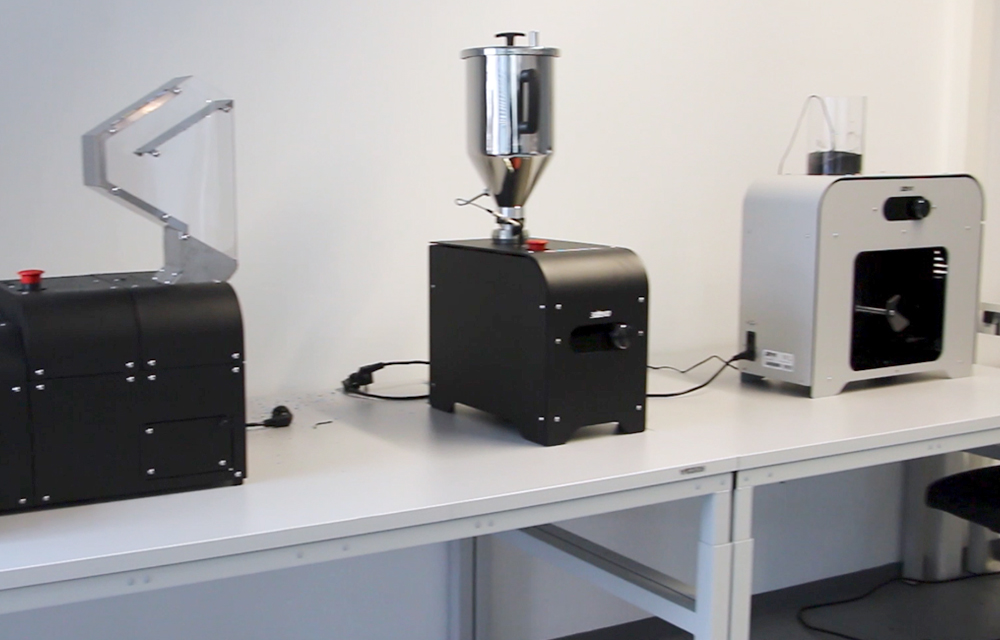

In order to establish a more sustainable use of plastics, the development of economic recycling cycles is a central step. The IPH has set up a recycling laboratory for this purpose: Existing premises were converted and equipped with a modern plant infrastructure. In the future, various research projects will focus on the topic of “plastics recycling for additive manufacturing”.

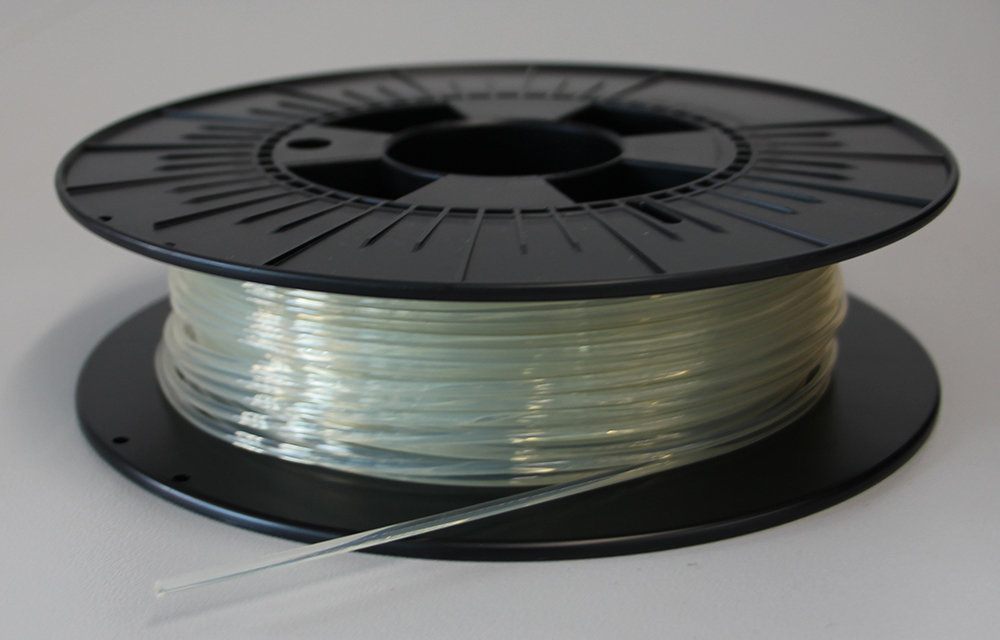

Waste becomes filament for 3D printing

The core of the plant infrastructure is a recycling process chain. With a near-infrared spectrometer, plastic waste can be identified and thus sorted. For shredding, the plastic waste is put into a shredder, which produces a uniform regrind. The moisture is removed from this regrind in a dryer before it is melted in the extruder and processed into filament by the integrated spool winder. The recycled filament can then be used in an additive manufacturing plant.

Recycling products on the test bench

Research potential also exists with regard to the qualification of recycled and additively processed plastics. For example, the repeated recycling of plastics results in changes in properties that can be quantified using appropriate test methods. In order to examine the mechanical and geometric properties of the end products, the IPH has therefore procured an optical 3D profilometer, a tensile testing machine and a pendulum impact tester.