Cryopreservation is the process in which biological material is frozen and stored at temperatures below -130°C. Automating such systems is very challenging, because the use of classical serial handling robots is nearly impossible due to the extreme temperatures. However, parallel robot structures allow the drives to be located outside the cold area, so that just passive components like hinges and arm limbs are exposed to low temperatures.

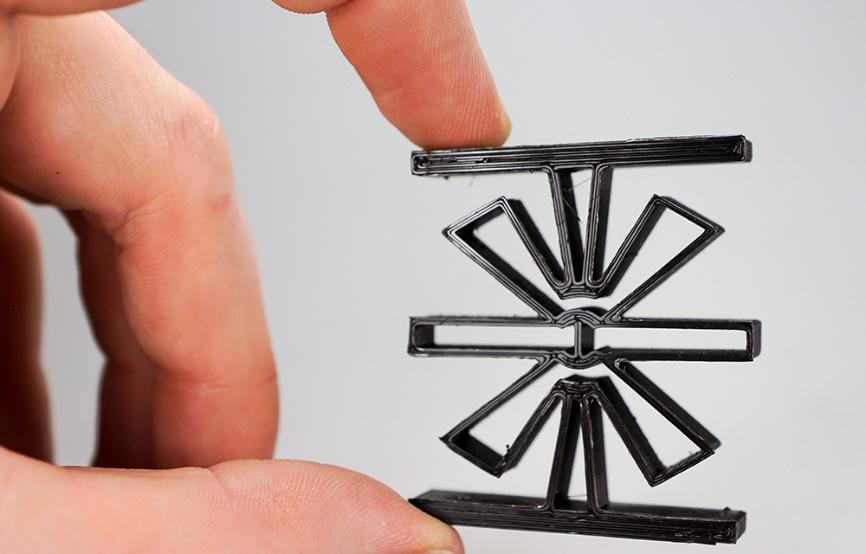

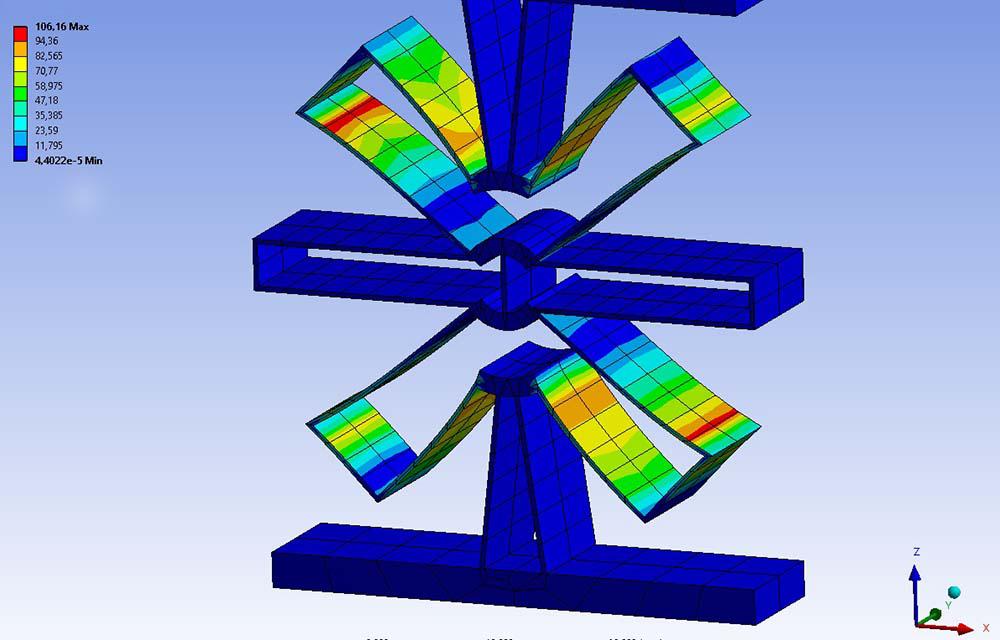

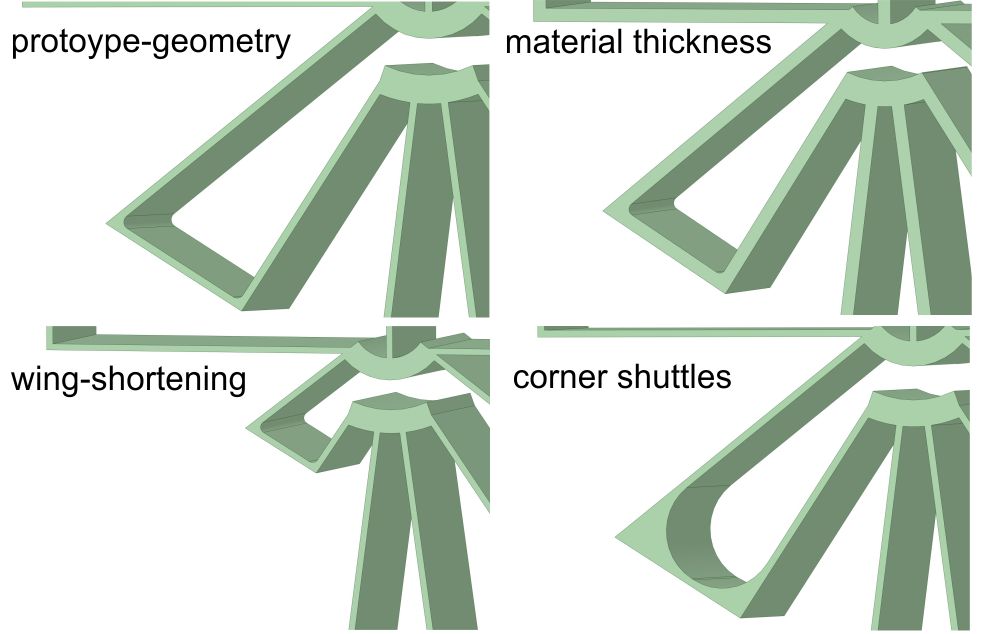

The Institute of Assembly Technology (match) is conducting research regarding the design of a robot-assisted handling and storage system for ultra-cold working environments. The researchers developed a cascaded flexure hinge (see Figure 1) und investigated by simulations how it performs under cryogenic conditions. To minimise unwanted deformations of the hinge like wings bending open (see Figure 2), the researchers have been testing various geometrical adjustments (see Figure 3).

The conclusion: Parameter optimisation reduces undesirable deformation of the hinge by up to 98% without limiting flexibility and without exceeding the maximum bearable stress in the hinge.