Can fiber reinforced plastics (FRP) replace metal components? Not so far – at present, processes for the production of sheet metal components dominate mass production because they are characterized by high productivity.

Although fiber-reinforced plastics have a great potential for lightweight construction, they cannot yet compete in terms of cost-effectiveness. Processing times and thus component costs have already been significantly reduced by replacing thermoset plastics with thermoplastics. However, the costs of a component made of carbon fiber reinforced plastics (CFRP) are still 7 to 9 times higher than for a comparable steel component.

Hybrid components made of metal and FRP

One approach to solving this conflict lies in combining the advantages of both materials. For example, metallic components in highly stressed areas can be specifically reinforced with FRP. This can significantly increase component stiffness and reduce component weight. Both steel and the cost-intensive CFRP are only used in the required quantities. Their mechanical properties are optimally utilized in every area of the component.

Up to now, such hybrid components have been manufactured using variothermal tools. For this purpose, the blanks of the individual material components are heated in a tool so that the plastic components are heated to melting temperature. Only then does the actual forming process begin. The tool is then cooled down by means of water cooling, the plastic components solidify and the component can be removed. Such a process takes about five minutes – far too long for large-scale production.

Goal: reduce production time

Processing methods suitable for large-scale production do not yet exist. Scientists at the Institute of Forming Technology and Machines (IFUM) and the Institute of Assembly Technology (match) of the Leibniz University of Hannover are currently working on a solution.

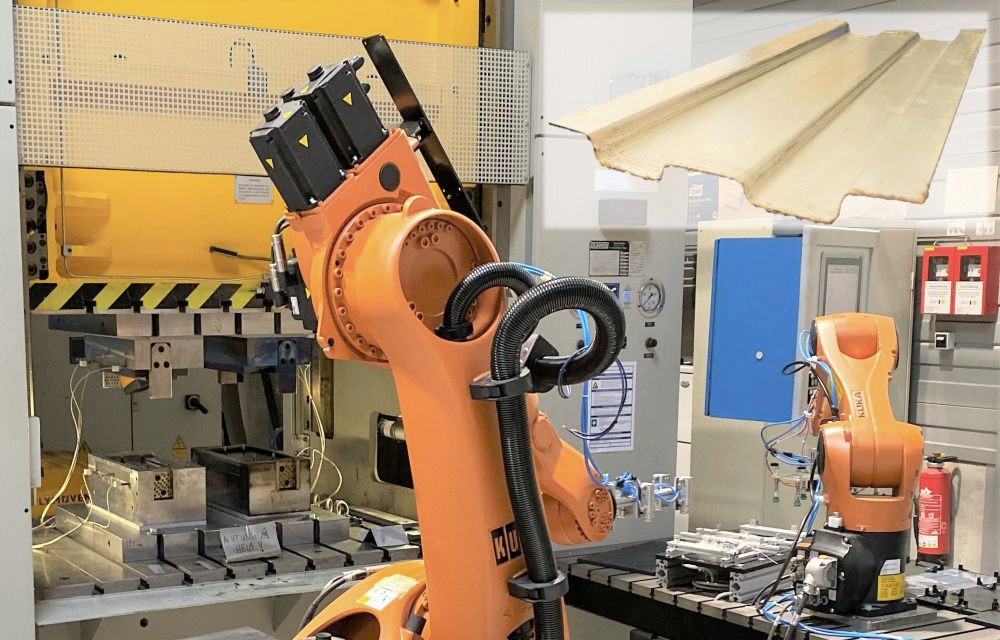

The aim of the scientists is to significantly reduce the manufacturing times for hybrid components. For this purpose, a new manufacturing concept was implemented at IFUM. Within the framework of the research project “Load-compatible FRP/metal composites”, the scientists have developed an experimental setup. It consists of two robots (see figure 2) and a two-part isothermal tool, which was integrated in a hydraulic press at the IFUM (see figure 3). This experimental setup is used to produce sandwich components which are based on the geometry of a roof crossbeam. The components consist of 0.3 mm thick DC03 cover sheets, two layers of PA6 foil and fully impregnated unidirectional CFRP tapes in the core.

Production in a 30-second cycle

At the beginning of the process, the first robot stacks the individual components and joins them selectively. This prevents the individual layers from slipping during further handling. The stacked materials are then inserted by the second robot with a magnetic gripper into the heating tool, which is permanently heated to 270 °C, and the forming press closes. The PA6 film reaches melting temperature in less than five seconds. The tool is then opened again and the robot transfers the heated sandwich to the forming stage of the tool, which is heated to 100 °C, and places a new stack in the heating tool for heating.

The temperature of the forming tool is selected so that the semi-finished sandwich product can be formed and the plastic solidifies so that the robot can remove the component immediately after opening the press. The hybrid components can be produced in a 30-second cycle using this procedure (see video).

Investigation of the component quality

Temperature-time management is of crucial importance for successful component production. Both tools are each heated by a heating coil and are equipped with thermocouples for temperature monitoring. At 270 °C, the temperature of the heating tool is just below the decomposition temperature of the PA6 plastic. This means that temperature losses due to transfer to the forming stage can be compensated, as otherwise the plastic starts to solidify again at 220 °C.

In the further course of the project, the scientists will investigate the influence of the temperature of the forming stage, the holding time in the die and the press force on the component quality. For this purpose, three-point bending tests were carried out and the hybrid components were compared with a monolithic steel component. Initial comparisons showed an increase in specific load capacity of 12.7 %. In addition, microscopic images were taken to detect air inclusions in order to assess the quality of the consolidation process.

Funding information

The IGF project 19603 N of the European Research Association for Sheet Metal (EFB) e. V. is funded via the German Federation of Industrial Research Associations (AiF) as part of the program to promote joint industrial research and development (IGF) by the Federal Ministry of Economics and Energy on the basis of a resolution of the German Bundestag. The author thanks the AiF and the EFB for their support. Further thanks go to the member companies of the project-accompanying committees and their representatives for their support of the project and the good cooperation.