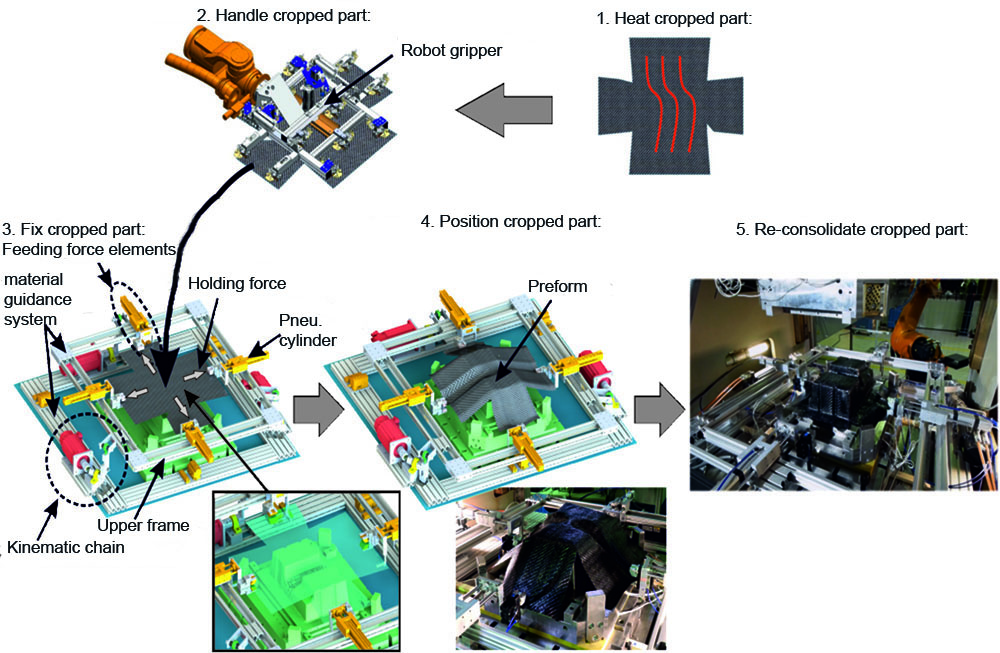

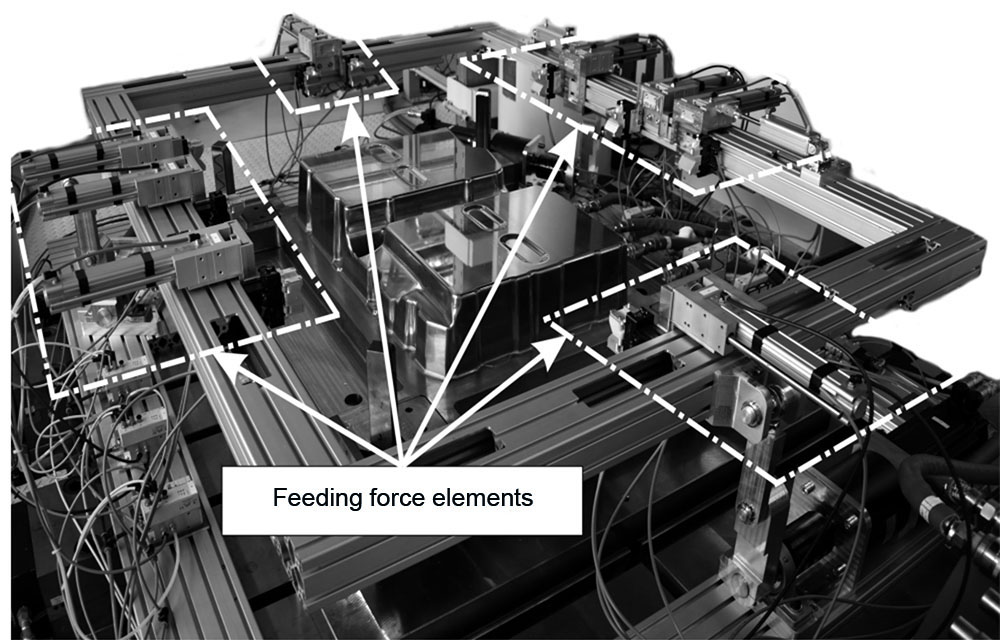

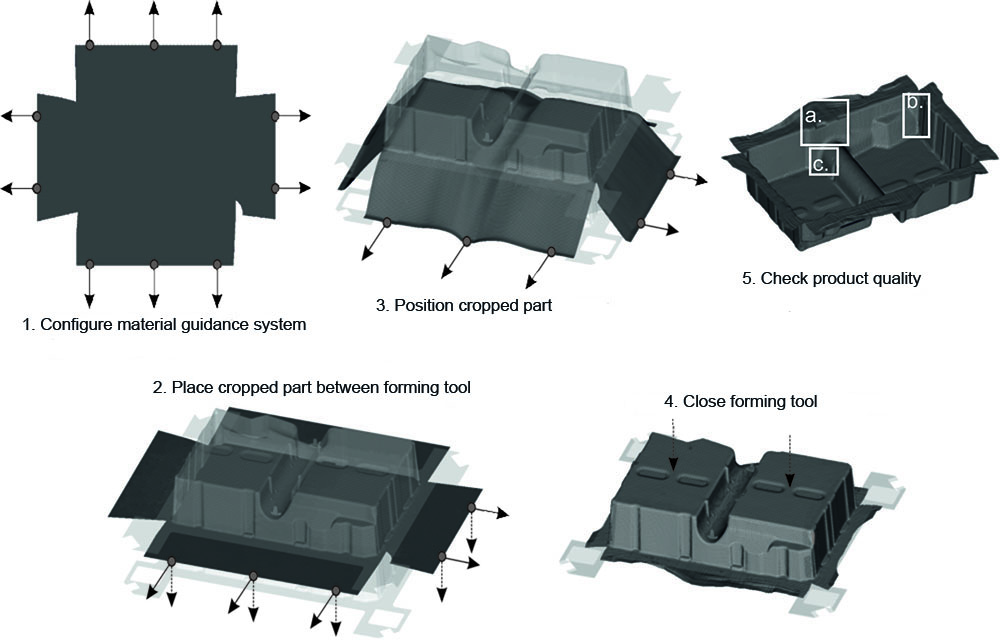

Fibre-reinforced plastics (FRP) have become indispensable in modern automotive lightweight construction. However, high flexibility requirements of FRP manufacturing processes inhibit the automation of the mostly inflexible processes with long changeover and start-up times. The reasons are the increasing variance of many products resulting in small lot sizes. This is exactly where the joint project ProVorPlus on “Functionally integrated process technology for preassembly and component manufacturing of FRP metal hybrids” of match and the Institute of Forming Technology and Machines of Leibniz Universität Hannover starts. The project aim is to overcome automation problems like robot-assisted handling of dimensionally unstable cropped FRP parts, which apart from that, are mostly plain and may assume very complex geometries.