The Institute of Assembly Technology (match) is researching shape-variable grippers for handling hybrid, forge-hot components as part of the Collaborative Research Centre (SFB) 1153 “Process chain for the production of hybrid high-performance components through tailored forming”. Here, the adaptability of shape-variable grippers to a wide variety of geometries is to be transferred to the forging sector. This is desirable because the components undergo significant geometric changes (see Fig. 1), and specially adapted grippers are required for handling, which can only be used for the geometry in question.

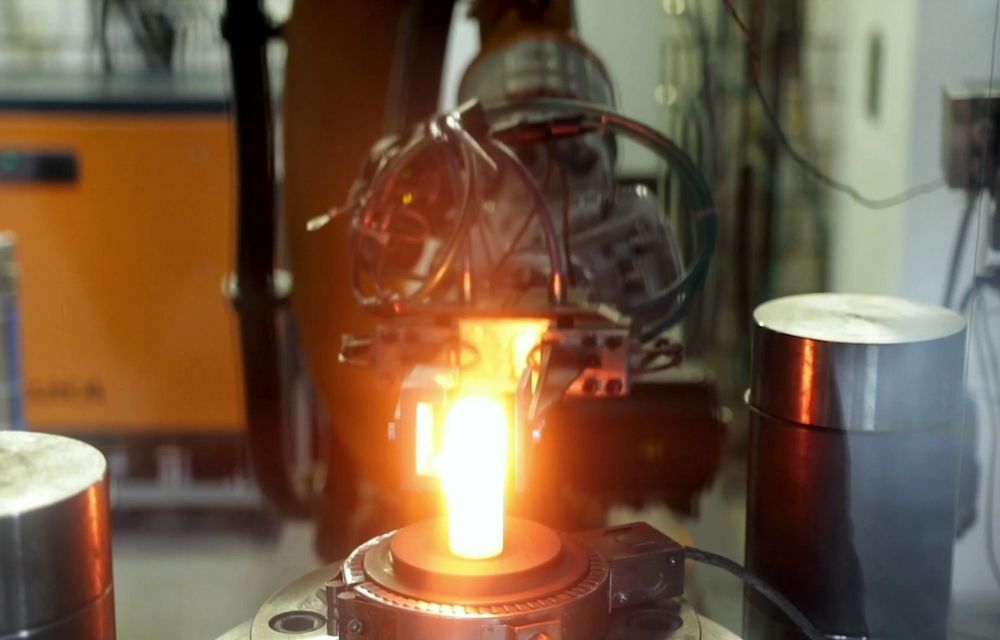

The problem is that commercially available variable-shape grippers are usually made of polymer materials. The material gives the grippers elastic behaviour, allowing them to adapt to different geometries. However, polymer materials are severely limited by their operating temperatures and can be used up to 300 °C. Hot-forged components, however, reach temperatures of up to 1200 °C (see Fig. 2).

To close the gap between form variability and high temperatures, the researchers at match first analysed and evaluated existing systems. Two systems have shown the potential to overcome the challenges: First, the so-called FinRay effect, and second, a pin gripper.

FinRay gripper: As flexible as a fish fin

The FinRay effect is a mechanical adaptation of a fish fin: an isosceles triangle whose legs are connected by cross beams. Due to its structure, this “fish fin” can deform in the opposite direction to an acting force. This causes the fin to form around an object when contact occurs. This effect is transferred to the gripper fingers, enabling them to conform to any contour. FinRay fingers are already in use in industry and are made of an elastic polymer material.

The match approach is to replace the legs with a link chain, as in wristwatches, for example (see Fig. 3). In this way, the FinRay finger remains movable, and a metallic material is used that can cope with the high temperatures. To this end, designs are first developed and tested by simulation, followed by the production of functional samples tested on hot components.

Pin gripper: Individual, positive-locking grip

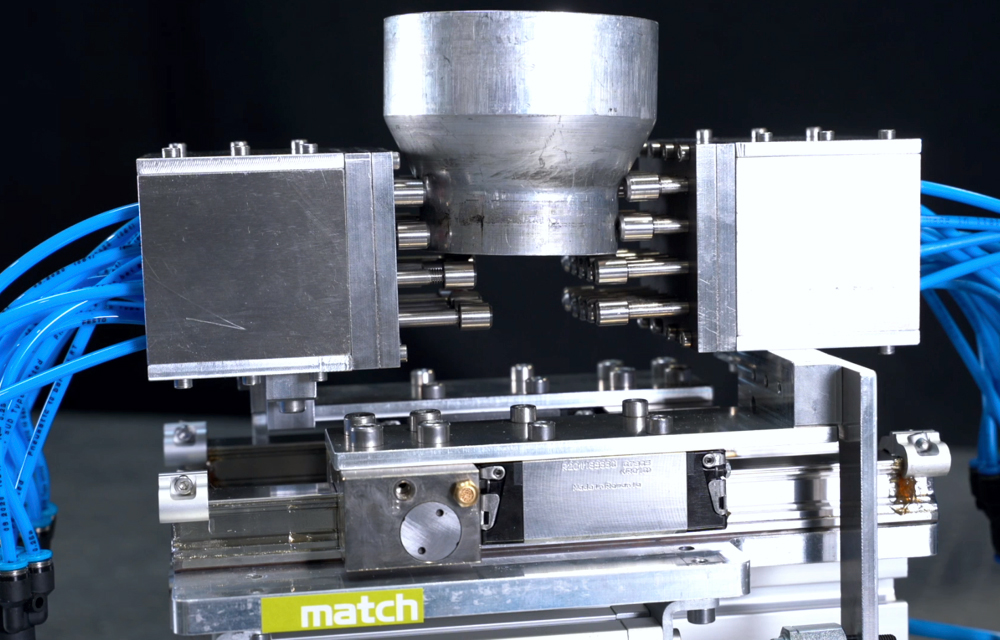

The pin gripper is a system in which pins are arranged in a matrix and can move axially independently of one another. The component to be gripped is placed between two opposing matrices, and the pins are then pushed out until contact is made with the component. Since the pins are self-sufficient, each pin reaches an individual end position. As a result, each contour is mapped at discrete points, and the pins map the negative shape, creating a positive grip.

Such grippers are made from metallic materials but are not designed to withstand high temperatures in the forging sector. The researchers at match evaluate and validate their suitability for use under forging conditions and optimise the grippers accordingly. The prototype has been manufactured at match (see Fig. 4) and is being prepared for tests on hot components. This also includes the system’s programming that ensures safe operation during the tests with hot components.

Spray cooling: maintaining optimum temperature

In addition to gripper development, the match is working on integrating other features that enhance the quality of hybrid forgings and support their production.

One challenge is setting and maintaining a defined temperature gradient in the parts. The gradient is necessary to form the hybrid component, consisting of two or more materials. Otherwise, local melting may occur because one material requires forming temperatures that exceed the melting temperatures of the other material, and the melting would cause the component to be unusable.

Here, the researchers at match are pursuing the approach of spray cooling. This consists of nozzles that variably mix water and air, creating a fine spray. Due to the variable mixing ratios, a broad spectrum is achieved for the cooling capacity, which can be individually adjusted. The cooling system is designed so that it can be attached modularly to the previously mentioned grippers.