Whether in electrical engineering, power generation, transportation or aerospace – the fundamental physical properties of all technical components are generally determined by the selection of the right materials. For further developments in almost all technological areas, the materials used must therefore also become more efficient.

Alloy without main element

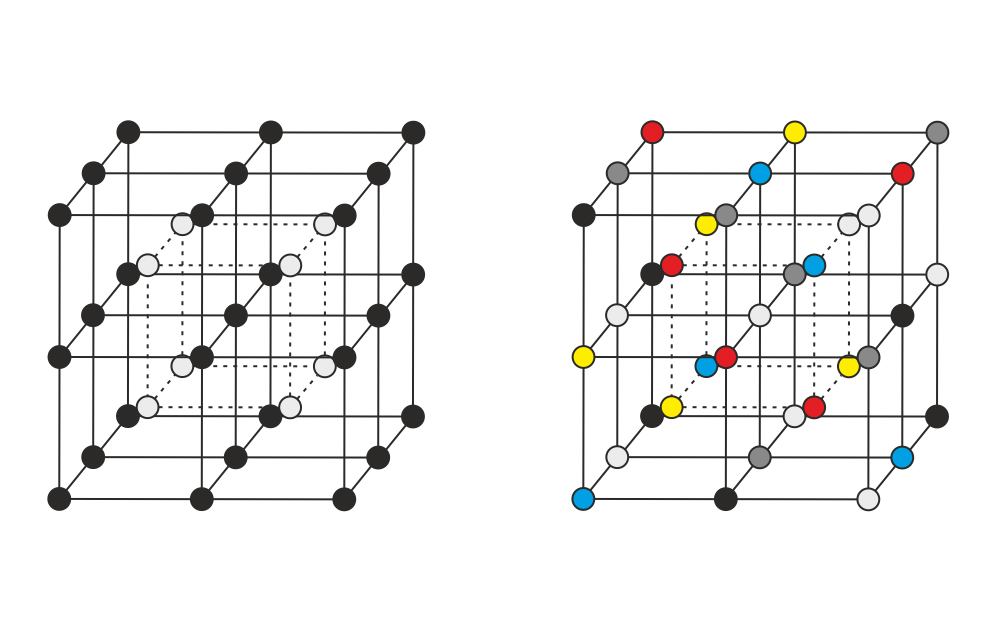

Metallic materials such as steels or aluminum alloys, which are conventionally used in a wide range of applications, consist mainly of one main element and some important secondary elements in low concentrations. In steels, iron as the main element usually has a mass fraction of more than 90%. The main element as the basis determines the overall properties of a material, such as strength, ductility and hardness; these properties can be improved within certain limits by the addition of secondary elements. The main element also determines the crystal lattice and thus the regular internal arrangement of the atoms in a material.

But what happens when there is no single main element alone, but instead there are five or more elements that together take the main role? Researchers at the Institute of Materials Science (IW) at Leibniz University Hannover are precisely investigating this question and are working on so-called high entropy alloys as part of the Priority Program 2006 of the German Research Foundation (DFG).

High entropy alloys

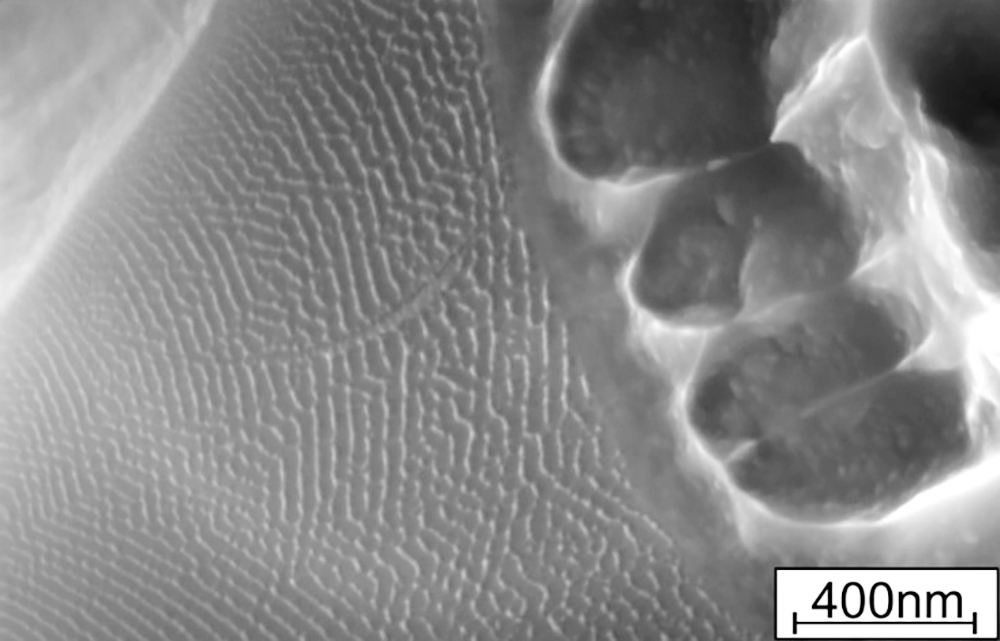

The new class of high-entropy alloys (HEA) refers to metals with five or more elements in almost the same concentration. This means that it is not a single element determines the order in the material and the resulting properties, but rather the large number of elements with a random occupation of the lattice sites. However, IW studies in this area have been able to demonstrate, despite the supposed chaos, a form of order that is somewhere between the classical order in conventional alloys and a chaotic distribution of elements.

This new concept of alloy design opens up a huge range of possible combinations with considerable technological potential. Unusual phenomena in microstructure and mechanical properties that cannot be achieved in conventional alloys are revealed. The Cantor and Senkov alloys, which are named after their discoverers, are particularly well known as pioneering alloy systems in this respect.

High entropy shape memory alloys

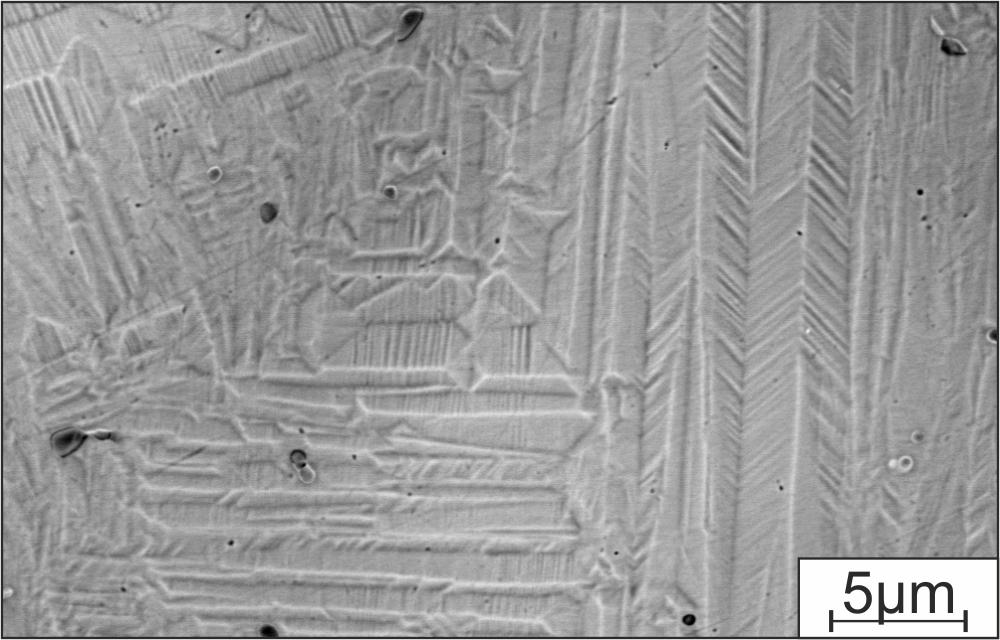

Researchers at the IW are going one step further and applying the described principle of high entropy alloys on the special field of shape memory alloys (SMA). The scientists are thus working on high entropy shape memory alloys (HE-SMA). These include TiZrHfCoNiCu (see pictures), an alloy of titanium, zirconium, hafnium, cobalt, nickel and copper.

Shape memory alloys are metals that have the ability to “remember” their original shape after being deformed by the application of heat and return to that former shape. Despite this outstanding property, the alloys have so far found little application in engineering. The reason for this is that the shape memory effect is not an ideal process, but is limited by process-related material defects. This limits the effect after only a few application cycles, so that economic use is mostly limited to selected areas such as medical technology.

The development of HE-SMA is intended to oppose the undesirable fatigue with the aid of lattice distortions and other HEA-specific properties. Within IW’s research, deformations occurring under more than 1500 MPa load have already been successfully restored by the shape memory effect. The inhibition of the effect described above, referred to as functional fatigue, has also been reduced. High entropy shape memory alloys are thus shown to be promising systems for the further development of shape memory alloys.

Goals of the Priority Program 2006

HEA research in the Priority Program 2006 of the German Research Foundation (DFG) aims at achieving a fundamental scientific understanding of material properties that are due to the high entropy effect. This includes the identification of specific properties that occur as a direct consequence of the salient features of HEA. Overall a fundamental understanding of the characteristic structural and microstructural features of HEA will be investigated – with particular emphasis on their influence on mechanical properties.

Further information on the entire 2006 DFG priority program can be found at https://www.sppccahea.uni-bayreuth.de.