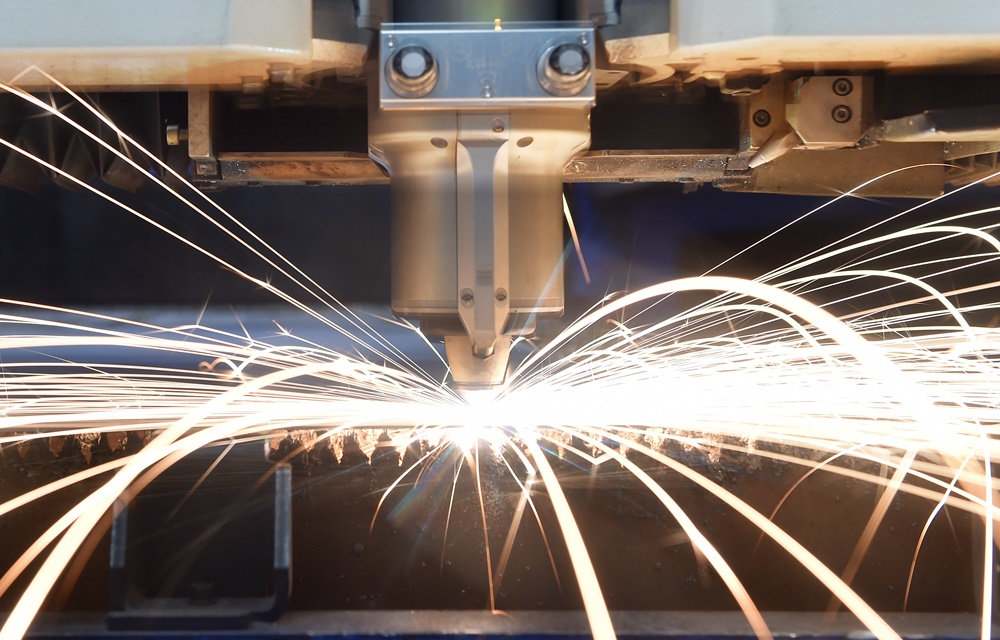

Visitors of EuroBLECH 2018 and everybody interested in the laser material processing of tomorrow can experience the latest trends at the Laser Zentrum Hannover e.V. (LZH) on 25 October 2018 from 11 a.m. to 5 p.m. During the "Open House during EuroBLECH 2018", the institute presents various laser systems live in action.

Laser joining, cutting and printing and process control

From 3D-printed parts made of metal and plastic to laser-assisted bomb defusing and laser-formed lightweight construction materials, the LZH shows an impressive range of laser processes and applications. Laser experts will be available as discussion partners for all questions about laser material processing.

The registration for this event is free-of-charge. Snacks are included. For information on the "Open House during EuroBLECH 2018" please see www.lzh.de/en/ohEuroBLECH18. Please register in advance at www.lzh.de/de/registration-ohEuroBLECH18.