In the FOR 5250 research group, an interdisciplinary team of experts from the fields of materials, medical and simulation technology is developing customized, additively manufactured implants for dentistry. The scientists want to create an alternative to standard dental solutions and manufacture implants that are individually adapted to the respective body. In this way, they aim to achieve higher tolerability and lasting functional performance of the implants.

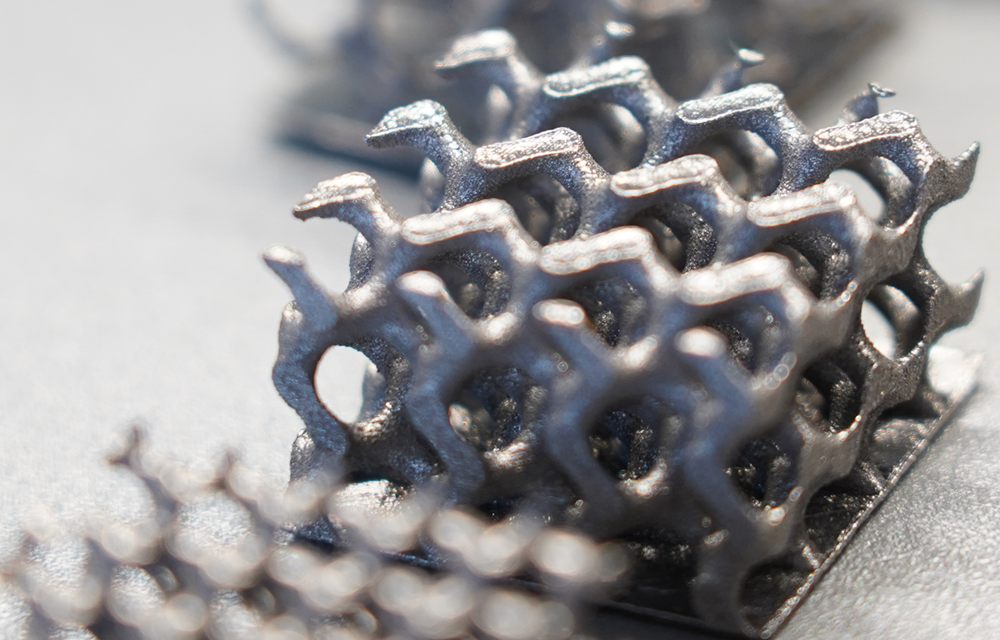

With Additive Manufacturing in the powder bed, implants can be produced that are precisely tailored to the needs of the patient. Within the framework of the research group, the LZH scientists are investigating the influence of various process parameters on the microstructure and mechanical properties of implants. They work with the titanium alloy Ti-6Al-4V, which is known for its high strength and corrosion resistance as well as its excellent biocompatibility. The researchers’ goal is to produce implants in which porosity, surface properties, and microstructure can be individually and precisely adjusted. This should improve tissue integration and thus also the longevity and functionality of dental implants.

Graded materials should make implants more resilient

The titanium alloy Ti-6Al-4V is known for its high strength and corrosion resistance. Due to its excellent biocompatibility, the metal is used in many medical applications, such as orthopedic surgery and prostheses. To be able to precisely adjust the stiffness of the implant, the LZH researchers use lattice structures. With the help of the lattice structures, they want to adapt the implant to the modulus of elasticity, i.e. the stiffness, of the human bone. In this way, they want to develop more resilient and ultimately more durable implants.

They also want to make use of the advantages of graded materials: By varying the lattice structure within the component, the implant has different mechanical properties. An important question for scientists is how these graded mechanical properties of additively manufactured implants can be adapted to given load scenarios.

Analysis of process parameters for reproducible production

The project participants will not only vary the lattice structures, but also the process conditions of the laser-based powder bedding process, such as the laser power. In this way, they want to gain insights into the influence of process and geometry parameters on the microstructure, mechanical properties, surface topography, and corrosion and failure properties of the implants. The findings should ultimately make it possible to adjust porosity, surface properties, and microstructure individually and precisely in each case to manufacture the implants reproducibly.

About the research group FOR 5250

The research group “Mechanism-based characterization and modeling of permanent and bioresorbable implants with tailored functionality based on innovative in vivo, in vitro and in silico methods (FOR 5250)” was initiated by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) at the end of 2021. The DFG is funding the group for an initial four years with around 3.4 million euros (project number: 449916462). It is located at the TU Dortmund.

Scientists from TU Dortmund, Laser Zentrum Hannover e.V., Reutlingen University, Hannover Medical School (MHH), University Medical Center Hamburg-Eppendorf, Rostock University Medical Center, TU Berlin, and Leibniz University Hannover are involved. The spokesperson of the group is Professor Dr.-Ing. Frank Walther from the TU Dortmund, the co-spokesperson is Prof. Dr. med. dent Meike Stiesch from the Hannover Medical School.