To withstand the increased cost pressure on the global market, producing companies have to adapt their strategies. Innovations in factory planning are a decisive factor for an increased efficiency, flexibility and changeability. However, factory planning processes are normally very complex and resource-intensive – a motivation for the Institut für Integrierte Produktion Hannover (IPH) gGmbH to develop an easily applicable low-cost method for three-dimensional factory layout scans.

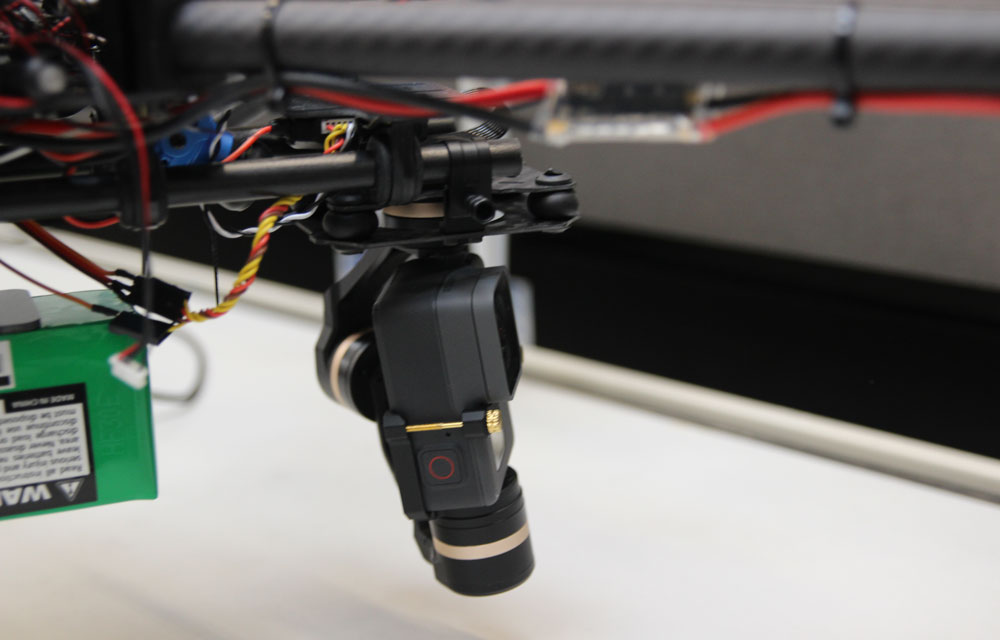

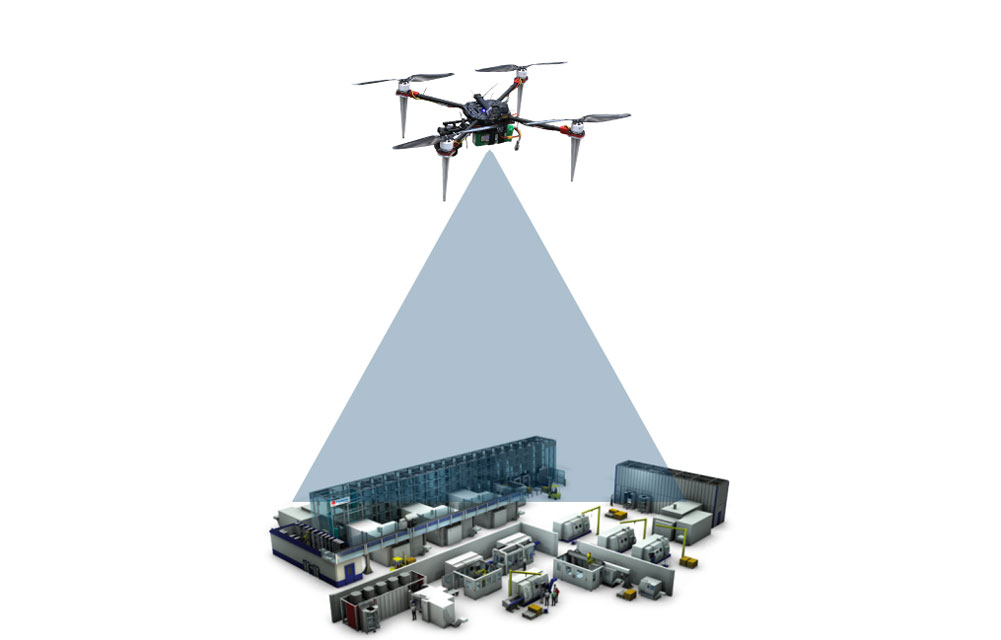

The idea: A UAV flies semi-autonomously across the factory facilities. The data scanned by the drone can be depicted as three-dimensional point clouds representing certain objects in the factory. In this way, the program steadily expands a database and keeps learning. The created three-dimensional model can be modified virtually to identify the most efficient layout.

The researchers’ aim is to develop UAVs that can fly autonomously across a factory to scan the layout. Algorithms could then use the data to create three-dimensional layout plans.