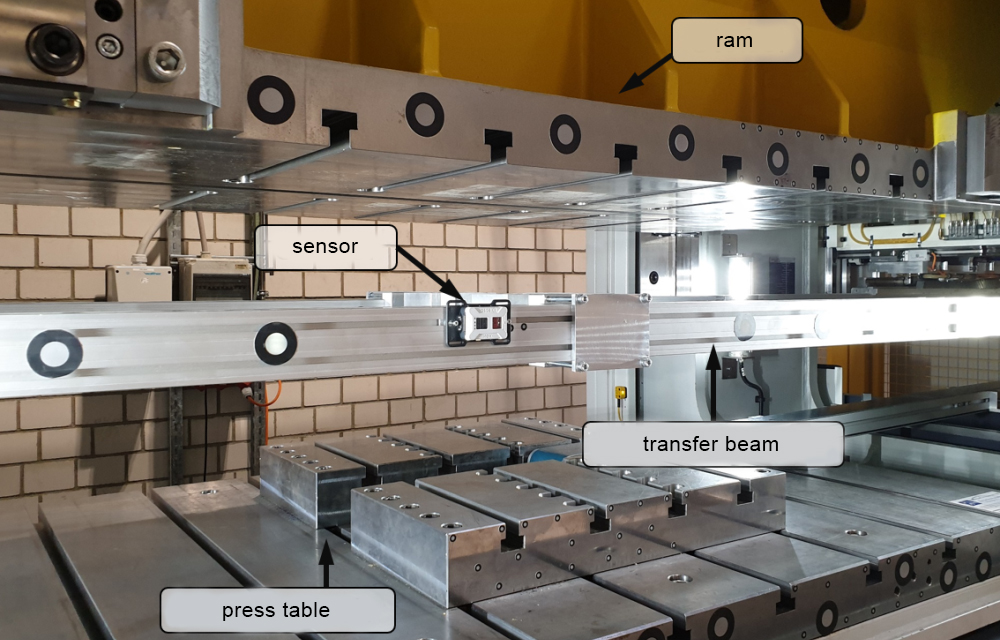

Within the scope of a research project, the researchers of the Institute of Forming Technology and Machines (IFUM) are currently developing a new method that optimizes the transfer kinematics depending on the particular vibration behaviour. Compared to existing approaches, the innovation is to apply a self-learning optimization algorithm without the need for detailed information on the system to be optimized.