ALD (atomic layer deposition) technology can produce very thin, high-quality coatings. The Spatial ALD system achieves high deposition rates in the production of ultra-thin coating systems for optics and enables the uniform coating of complexly shaped surfaces.

This is of interest, for example, in the fields of automotive lighting or augmented reality (AR)/virtual reality (VR), where three-dimensionally shaped lighting elements are essential. As the system is plasma-based, it can operate with low temperatures below 100 degrees – making it particularly suitable for coating temperature-sensitive polymer optics, which are often used for displays.

The rotation principle enables high deposition rates

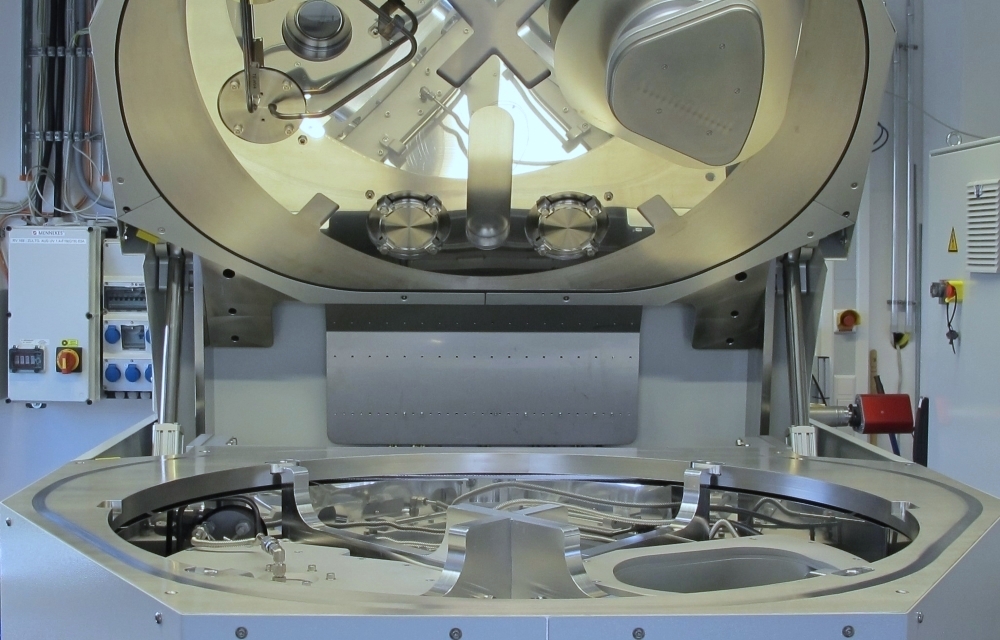

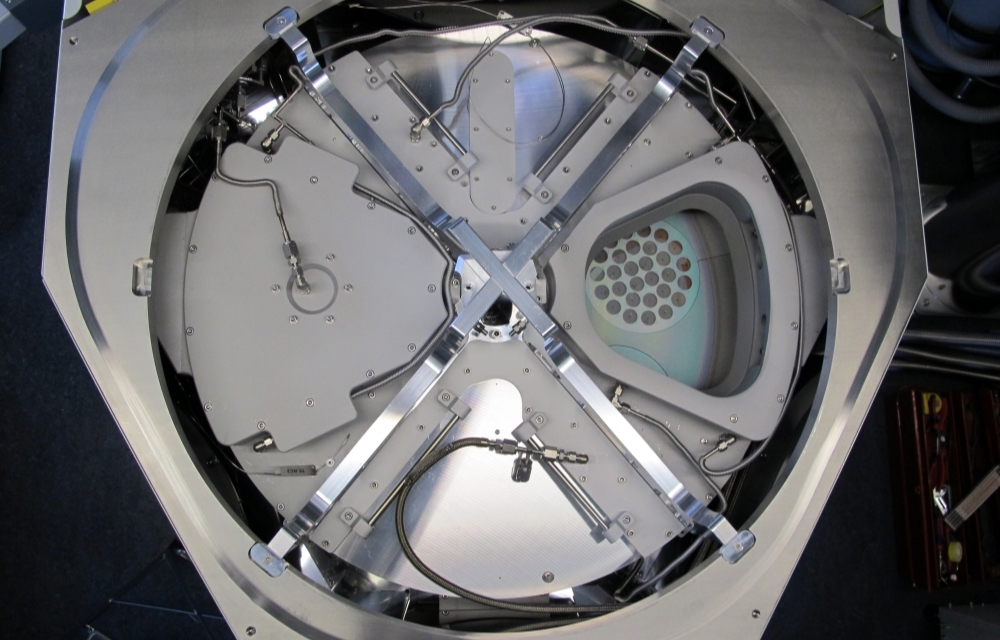

The ALD process is based on self-limiting chemical reactions between gaseous precursors and substrate surfaces. In systems commonly used at present, the process reactions are carried out one after the other, which necessitates a time-consuming gas exchange of the entire reaction chamber. This is different in the Spatial ALD system at the LZH: Here, the process cycles take place spatially separated.

The system has four individual process chambers separated by pressure and nitrogen, in each, an ALD reaction step is completed. The substrates then rotate into the next chamber. In this way, the scientists achieve deposition rates that were previously only possible with other coating processes. This makes the process particularly economical and at the same time enables high throughput in optical coating.

The system is of interest to both research and industrial customers: The LZH is open to challenges with the Spatial ALD system in the context of industry and research collaborations.

For questions about the ALD system, Dr. Andreas Wienke, Head of Optical Components Department at LZH, will be happy to help.