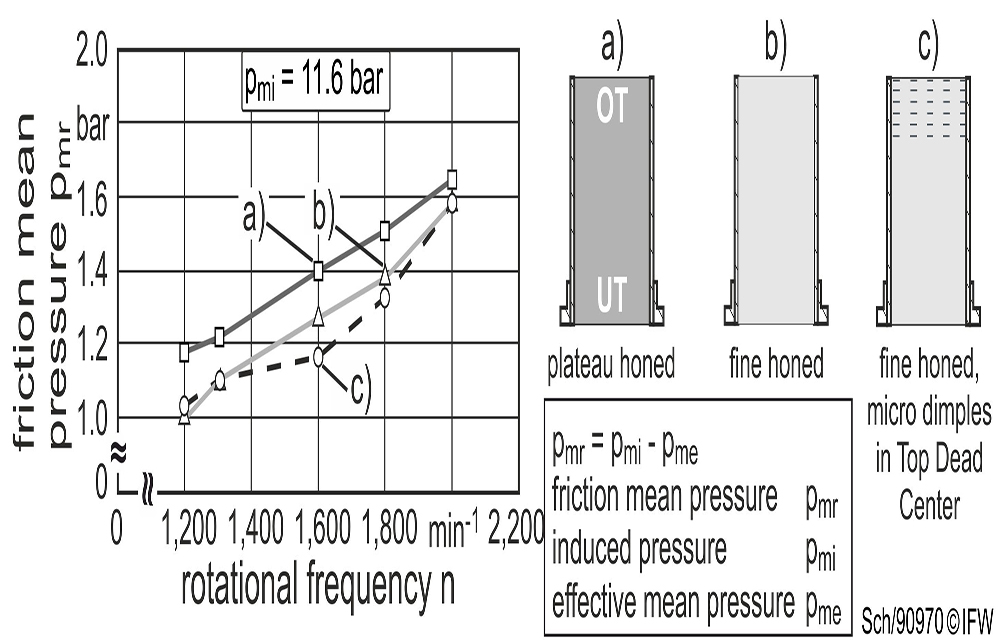

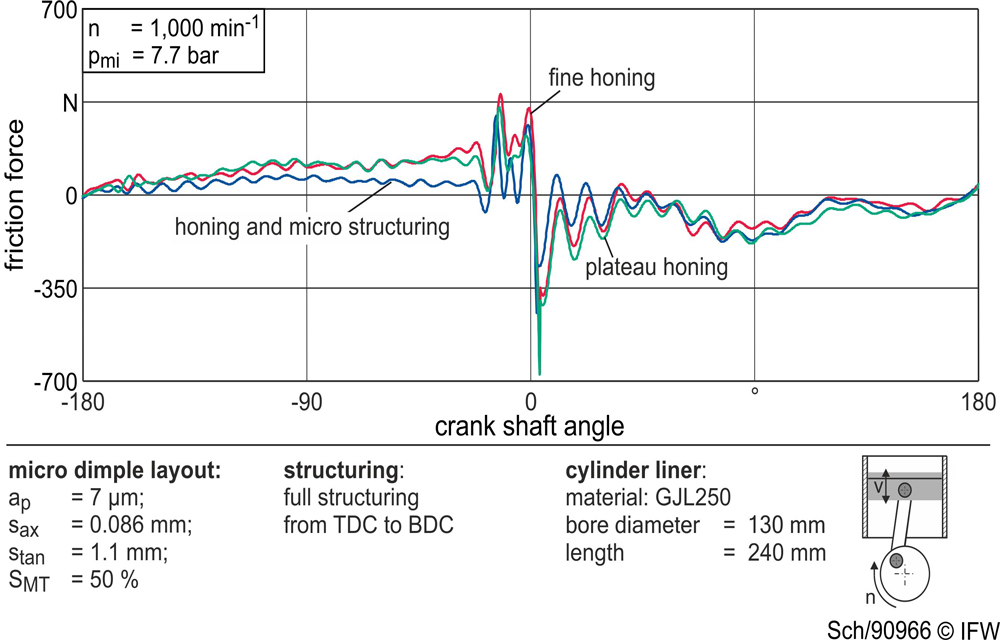

In Germany, about twelve percent of the CO2 emissions are produced by the transport sector. One reason is the low efficiency of under 40 percent of combustion engines which is caused by internal thermal and mechanical losses. About 50 percent of the mechanical losses in a combustion engine are due to friction between the cylinder liner and the piston with its piston rings.

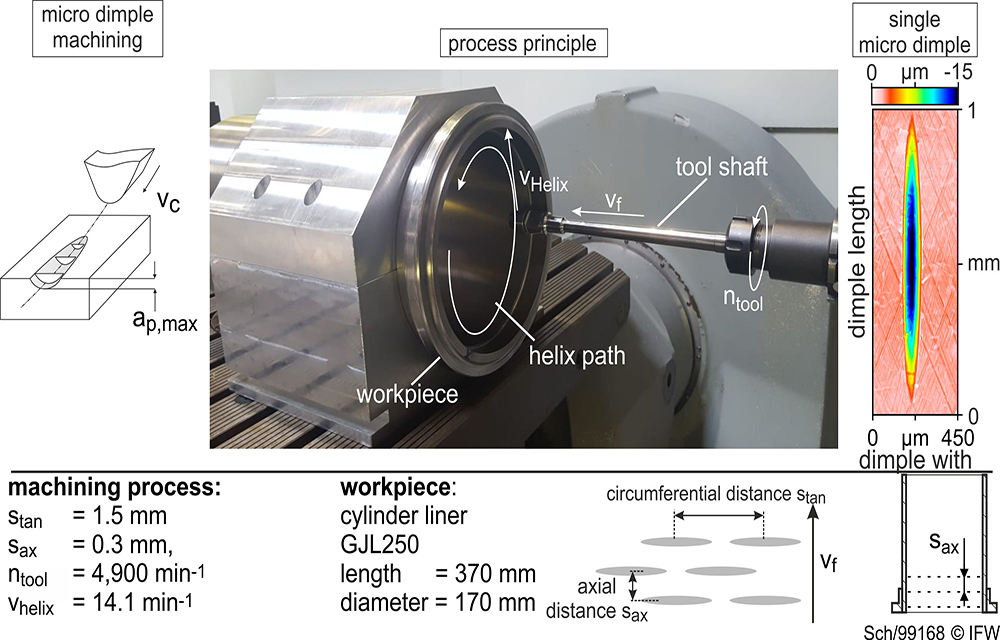

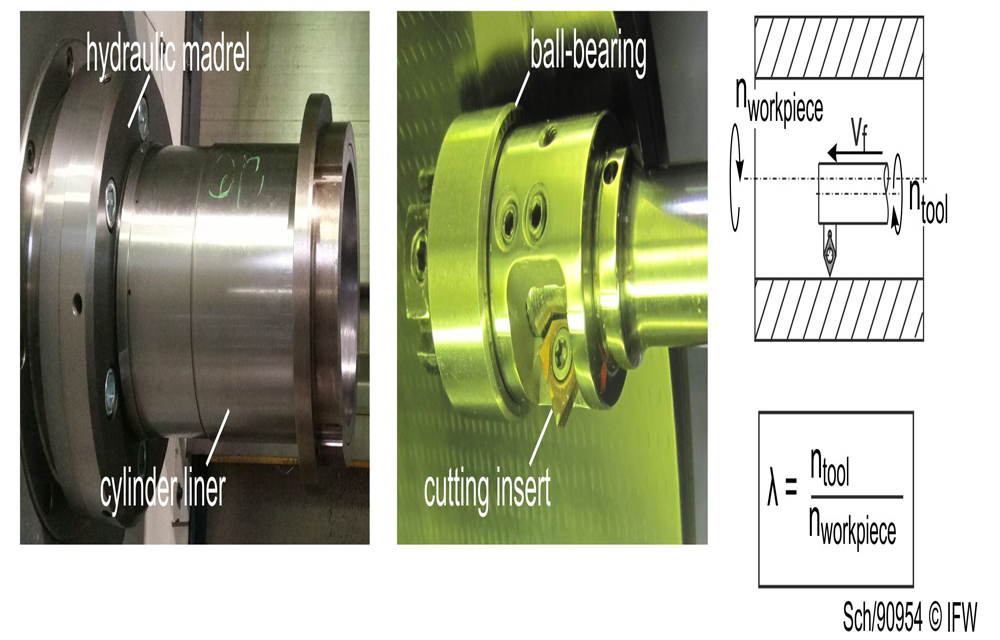

Within the scope of a research project, the Institute of Production Engineering and Machine Tools (IFW) and the Institute for Technical Combustion (ITV) of Universität Hannover are developing production strategies to reduce friction in heavy-duty diesel engines.