The identification of components is an important prerequisite for production and repair processes to be digitized: Only a precise assignment of the component and the storage of relevant product information enables the creation of a digital twin that accompanies the component through production. In the industrial environment, radio frequency identification systems (RFID systems) are often used to identify components. The system works with a passive RFID transponder (RFID tag) on the component and an active reader that writes or reads the information on the RFID tag. The information does not all have to be stored on the tag itself: Production data, material specifications and any other information can also be stored on a connected server.

RFID tags are classically applied to the outside of the product. Thus, they are not well protected from damage or tampering. With additive manufacturing, however, the tags can be implemented directly into the component. Niedersachsen ADDITIV has researched the extent to which this process can be automated.

FDM printing enables insertion of tags inside the component

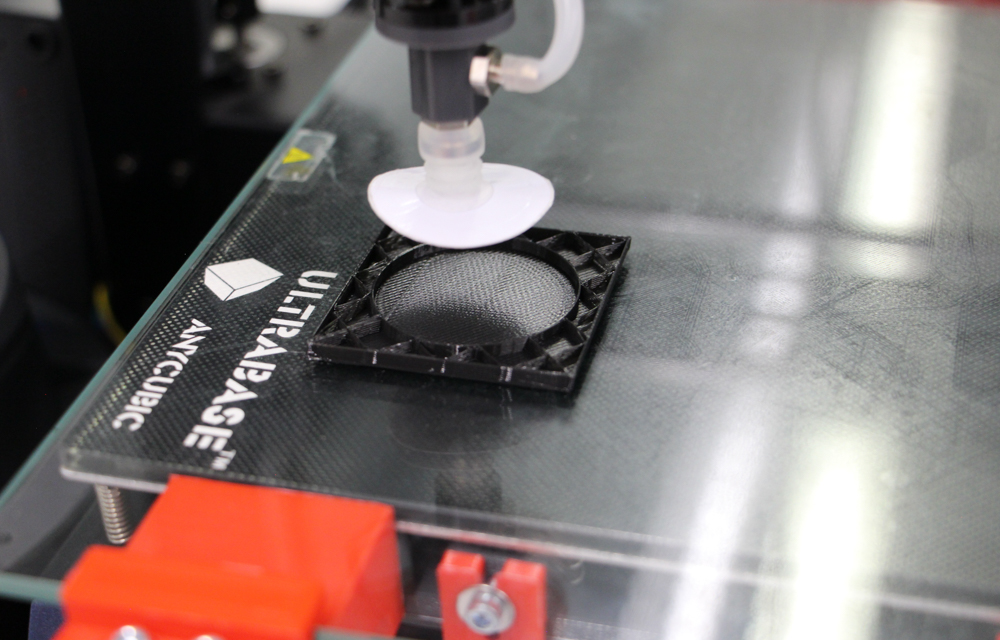

Due to the technical properties of commercially available RFID tags, only additive processes can be used in which the components are not subjected to temperatures higher than approximately 250°C. Furthermore, in order to insert a RFID tag into the printing process, it must be possible to pause printing, insert the RFID tag at the position provided for this purpose, and then continue printing without errors. Both requirements are met by the Fused Deposition Modeling (FDM process): The installation space is freely accessible, and the printing process can pause at a defined position in order to insert the RFID tag into the component. The printing process can then be continued.

However, manual insertion of the RFID tag significantly increases the effort required for the otherwise fully automated printing process. Depending on the design of the component, the time at which the printing can be paused and the RFID tag inserted varies, making it difficult to plan the overall process.

RFID tag implementation in 3D printing: automation meaningful

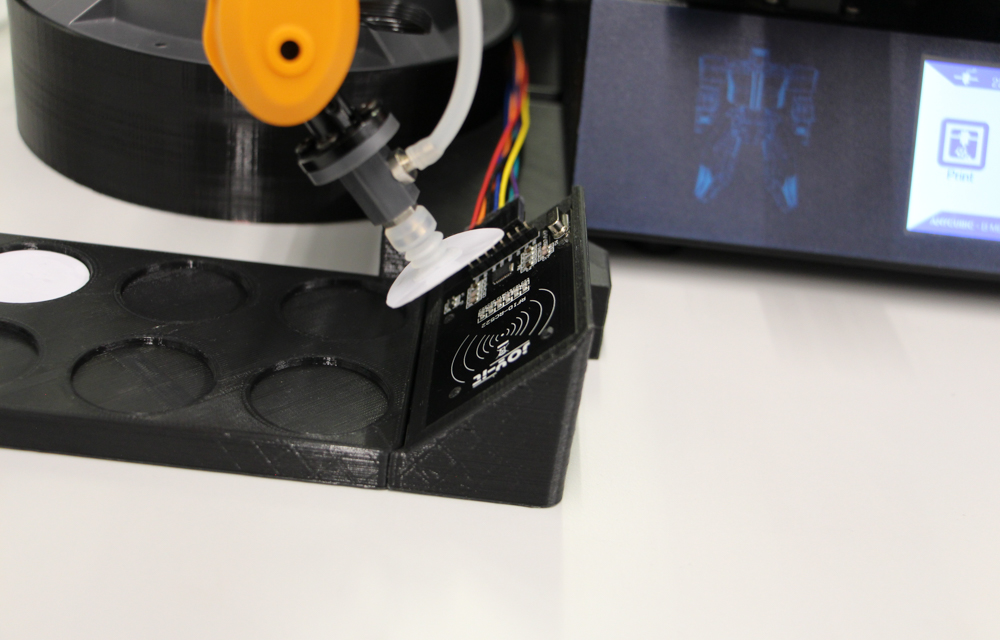

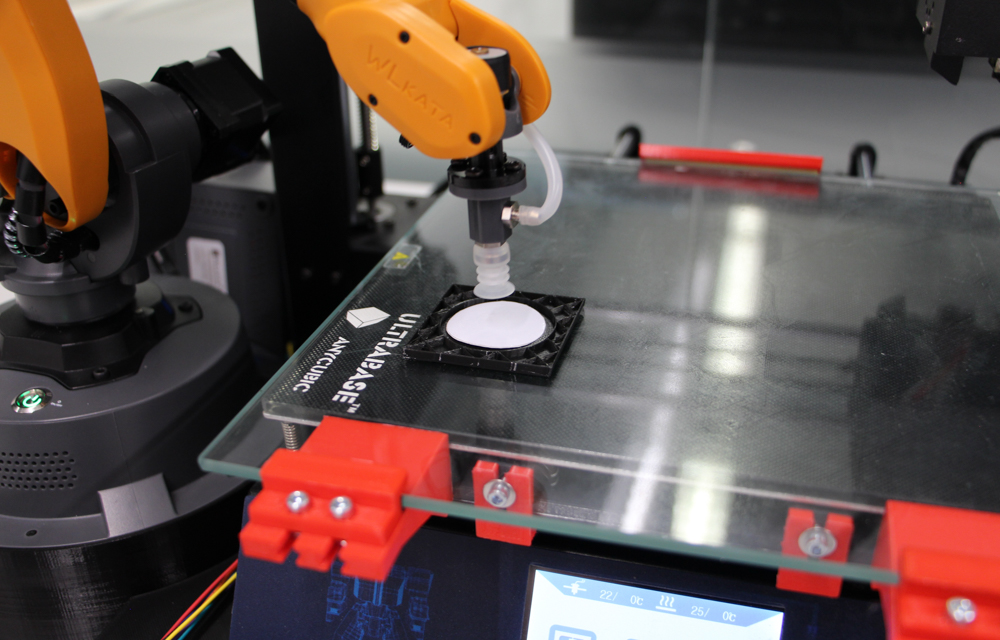

The team from Niedersachsen ADDITIV has therefore investigated how the insertion process can be automated with the help of a robot arm. In the practical implementation, a small robot arm with a cantilever of approximately 35 cm and a pneumatic suction cup was positioned next to the 3D printer. Next to it was a container for RFID tags. The robot arm took a tag out of this and passed it over a read/write device, where it was automatically written with component data. The robot arm then inserted the RFID tag into the printed product.

The point in time of the insertion process was marked using a special G-code command before printing started, and the exact insertion position was stored in the central control system. When the G-code gives the command to start the insertion process, printing is interrupted for the duration of this process and the robot arm performs the insertion process.

Automated implementation not only interesting for RFID tags

The conclusion of Niedersachsen ADDITIV’s investigations is that the FDM process makes it possible to insert commercially available RFID tags directly into the component instead of just attaching them from the outside. Because the printing processes have to be interrupted at defined times for this, depending on the component, it makes sense to automate the insertion process.

This basic idea is not only interesting for the insertion of RFID tags. In the future, the automated insertion of other functional elements into 3D-printed components will also be targeted. By inserting threaded sleeves, even small threads can be integrated into 3D-printed components without the need for time-consuming post-processing, such as melting thread inserts. By automating this process, this would also be possible under economic conditions and could significantly expand the industrial application area of FDM printing.