Research

The future of production technology

- Research

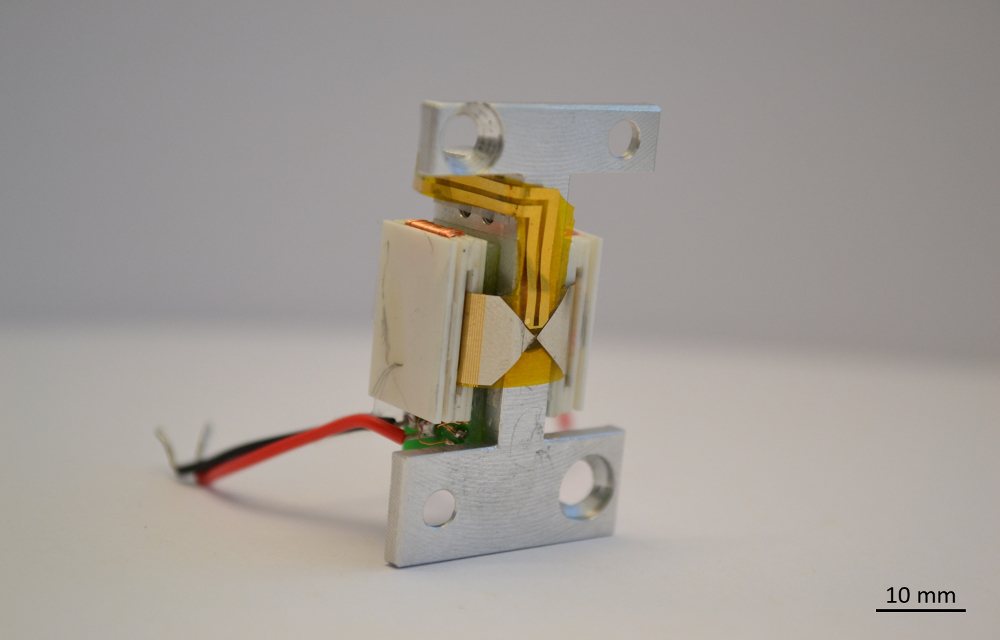

IMPT | Novel sensor concepts are supposed to facilitate strain and temperature measurement in future vehicle tires. In cooperation with Continental Reifen GmbH, IMPT is developing production concepts to implement micro components into rubber, which is a quite unusual substrate material.

- Research

IPH/IFA | Awkward bending, lifting heavy items, working overhead: Such movements may cause permanent health problems. As a preventive measure, researchers of IPH and IFA developed an ergonomics assessment tool for assembly workplaces: 3D cameras capture unhealthy movements automatically.

- Research

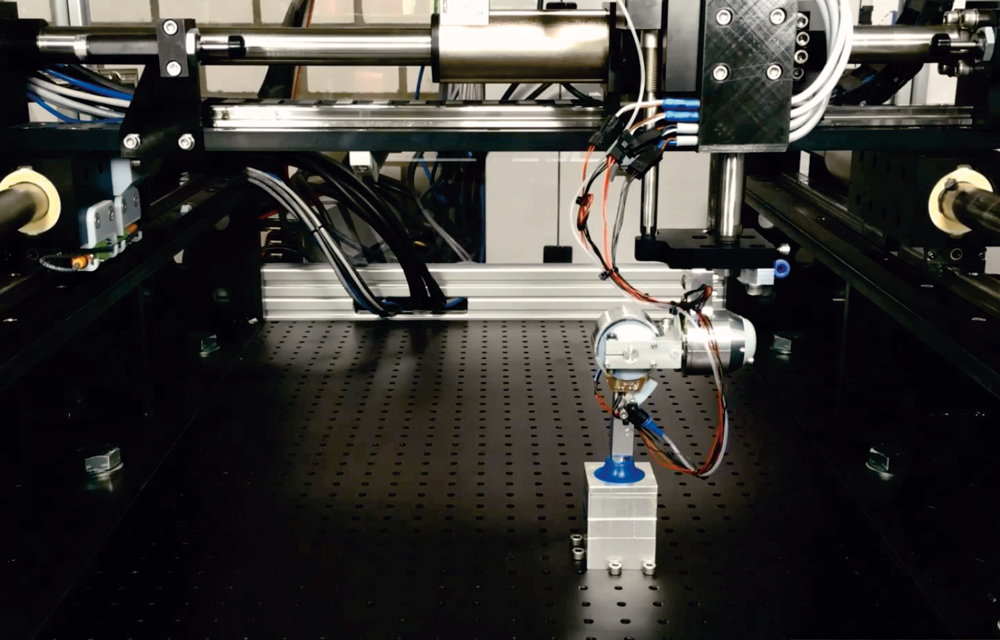

match | Passivity pays off – also in robotics. Researchers of the Institute of Assembly Technology (match) are currently developing systems with passive joints: Compared to conventional parallel robots, the advantages are higher flexibility, lower weight, reduced costs and easy reconfigurability.

- Research

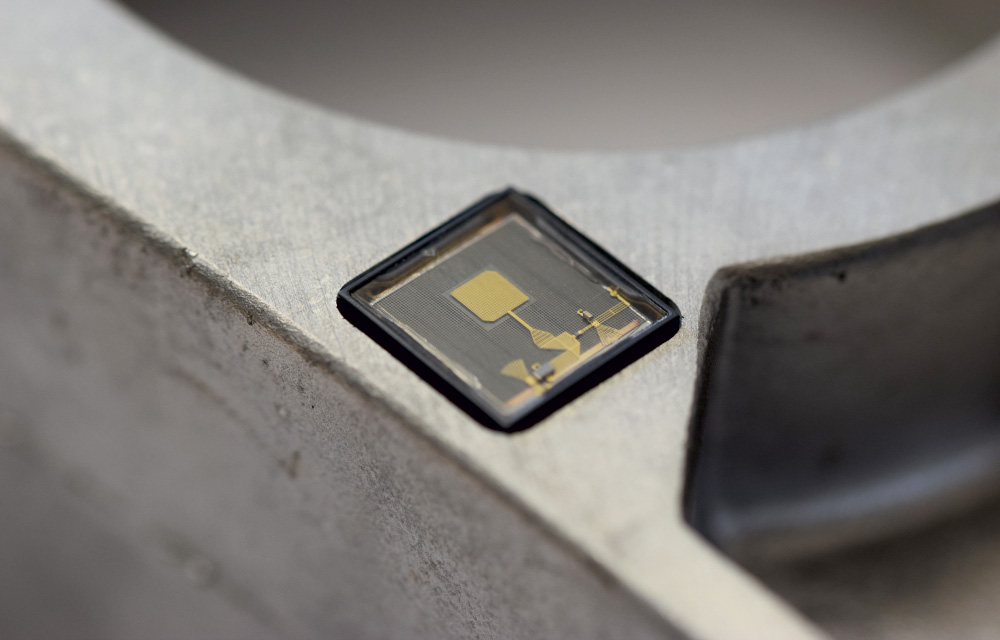

ITA | Researchers from Hanover have developed a communication module which is able to store and process component-relevant data and communicate it to its environment. The autonomous system is supplied by a tiny solar cell. Its overall size is only a quarter the size of a sugar cube.

- Research

IFA | With the Hanoverian Supply Chain Model, the Institute of Production Systems and Logistics (IFA) has developed a model which links the tasks of production planning and control with logistic actuating variables, control variables and objectives. The model is freely available on a web page for everybody.

- Research

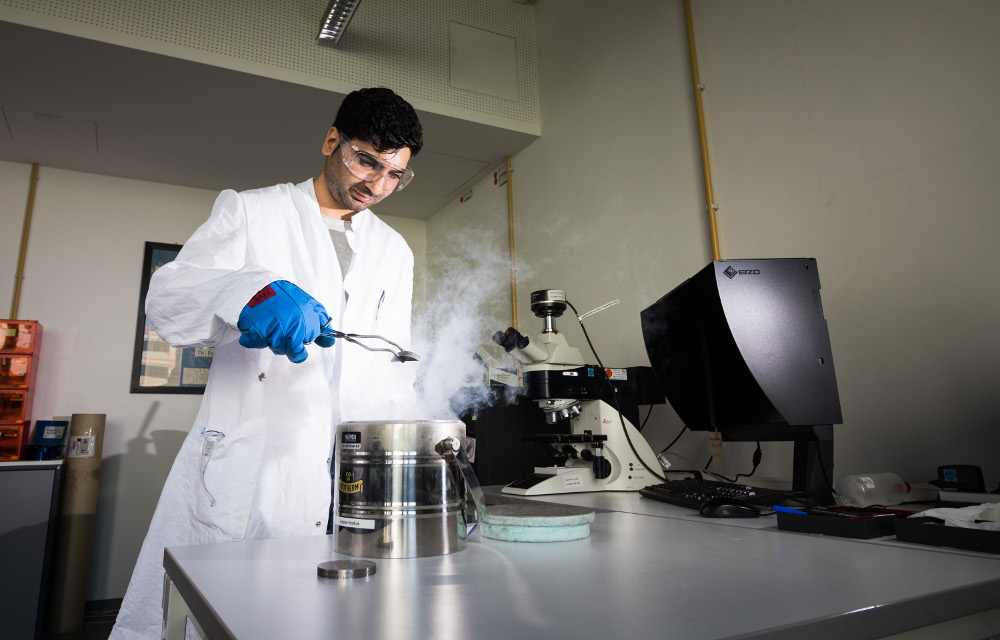

IW | Up to now, tool steels have been hardened by heat treatment. However, deep-freezing could improve wear resistance even more. For this reason, researchers at the Institute of Materials Science (IW) are investigating a method called cryogenic treatment, i.e. deep-freezing of steel using liquid nitrogen.

- Research

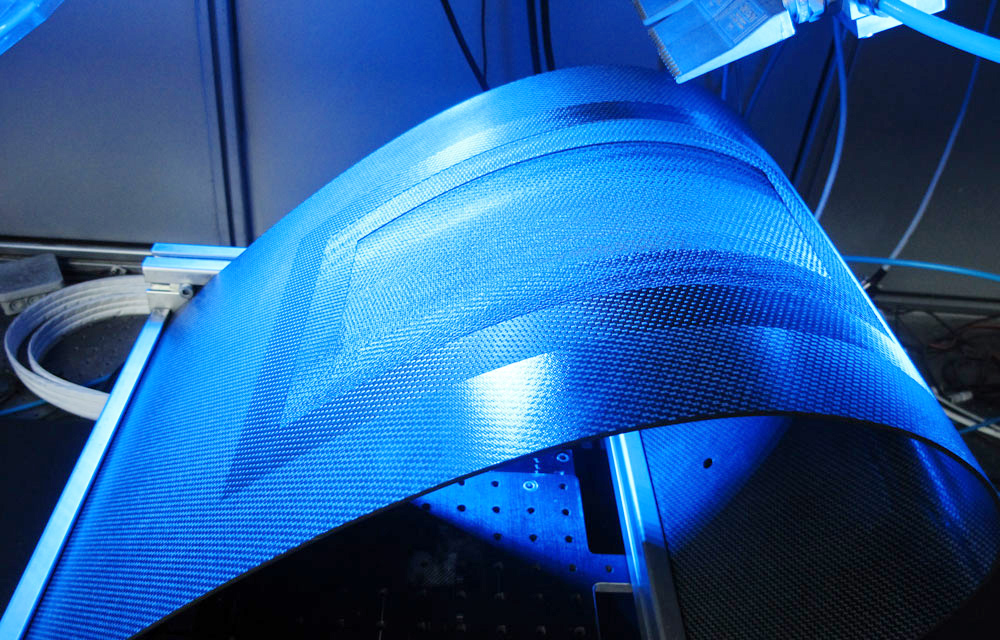

LZH | Fiber reinforced plastics (FRP) can be used to replace steel sheets, and thus lower the weight of automobiles and aircrafts. However, repairs are often expensive. The Laser Zentrum Hannover e.V. (LZH) is working on making repairs less expensive and more efficient.

- Research

IMPT | Researchers of the Institute of Micro Production Technology (IMPT) developed a magnetic data storage, enabling information to be stored directly on the surface of non-magnetic components.

- Research

IFUM | Apart from new materials and production processes, large-batch production of lightweight components also requires novel simulation strategies. Researchers at IFUM are currently developing calculation methods which are suitable for predicting the forming behaviour of fibre-reinforced plastics.