Research

The future of production technology

- Research

IFA | Implementing Industry 4.0 into their production helps SMEs to improve their efficiency – when selecting those methods and technologies which suit their company’s needs best. This approach is supported by researchers of IFA and wbk.

- Research

IMPT | Researchers of the Institute of Micro Production Technology (IMPT) of Leibniz Universität Hannover made a contribution to improve public security with the development of a micro-electron source for high-sensitive fire detectors.

- Research

IPH | Whether aircraft, ships or construction machines: The assembly of so-called XXL products requires a lot of space. Researchers at IPH are currently developing a method which enables companies to find an ideal layout. By this means, they can save space and increase their productivity.

- Research

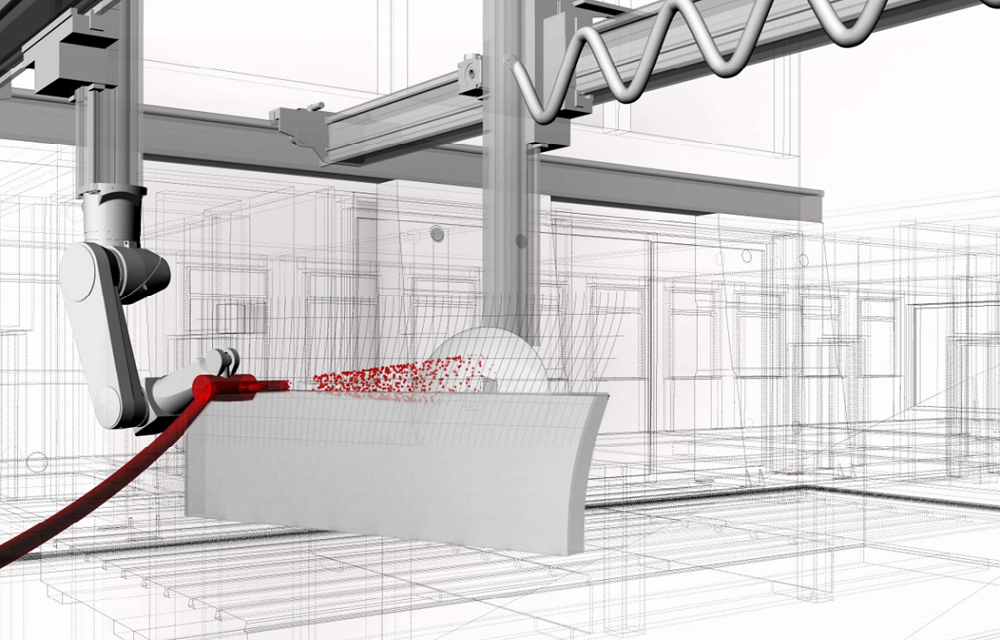

match | In future, manufacturing of concrete structures will be possible in any shape – thanks to robot-assisted concrete spraying technology. Researchers from Hanover, Brunswick and Clausthal are jointly working on the new technology – with virtually no design limits.

- Research

A novel drive concept for belt conveyors is under development at ITA in cooperation with IAL. Linear direct drives shall facilitate longer conveying distances and higher mass flows – with decreasing belt stress and tension as well as energy demand.

- Research

IW | Coatings protect components against wear, heat and corrosion. However, coating of very small inner diameters has not been possible so far. Researchers at the Institute of Materials Science (IW) are working on a solution – the transplantation of thermally sprayed coatings.

- Research

ITA | An innovative drive concept pushes previous boundaries of conveying technology: Driven idlers shall facilitate considerably longer conveying distances and larger mass flows. This novel technology is being investigated by researchers of the Institute of Transport and Automation Technology (ITA).

- Research

IFW | How can turbine blades be repaired to restore the shape without their surface suffering a loss of smoothness and aerodynamics? This problem is investigated by scientists of the Institute of Production Technology and Machine Tools (IFW).

- Research

IW | Up to now, aluminiferous stainless steels can only be brazed under high vacuum at very elevated temperatures – a complex and expensive process. Researchers at IW-FORTIS have developed a more efficient alternative: Special carrier gases enable brazing even under low vacuum.