Welcome to the news portal phi

The magazine for production research from Hanover

- Research

match | Above all, high-quality goods shall be disassembled at the end of their lifetime, either to get them repaired or to reuse their components. This can be achieved by component-friendly disassembly processes, increasing sustainable reuse of products considerably.

- Research

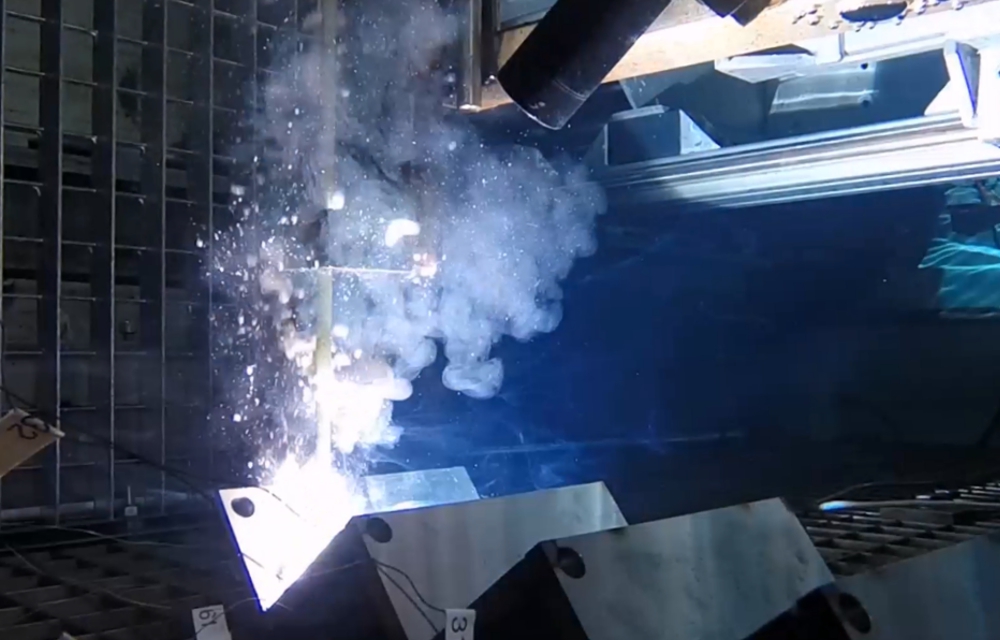

IW | Repair work carried out at offshore wind turbines poses new challenges: Researchers of the Institute of Materials Science (IW) generate data to make the finite element method also usable for the simulation of wet underwater welding.

- Smart minds

LZH | On April 16th, 2018, Dr.-Ing. Stefan Kaierle takes over the scientific and technical management of the Laser Zentrum Hannover e.V. (LZH) together with Dr. Dietmar Kracht. He succeeds Prof. Dr.-Ing. Ludger Overmeyer, who takes over the Chairmanship of the Scientific Directorate from Prof. Dr. Wolfgang Ertmer.

- Research

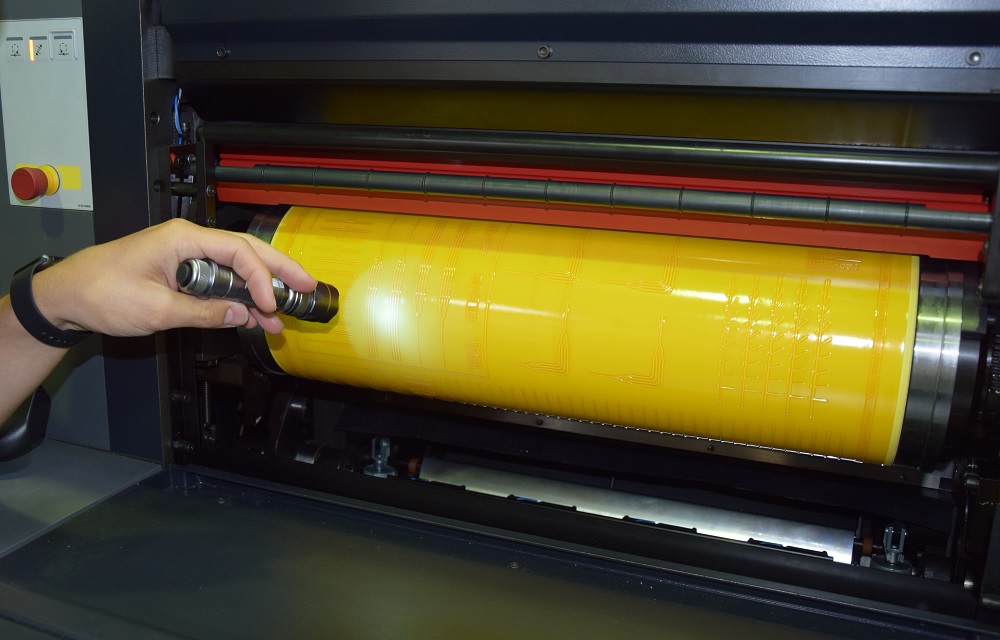

ITA | In future, printed optical waveguides will be used for multimedia transmission in cars and aeroplanes. The requirements are correspondingly large bandwidths and three-dimensional forming. DFG approves another three years of research of OPTAVER research group, in which scientists from ITA and LZH work together with fellows from Nuremberg, Erlangen and Dresden.

- Here & now

Match/IFA | The project SafeMate focuses on general implementation strategies for an accepted and safe human-robot collaboration. A team of researchers will present the research work using the exemple of the assembly of a washing machine at automatica 2018 in Munich from 19 to 22 June.

- Here & now

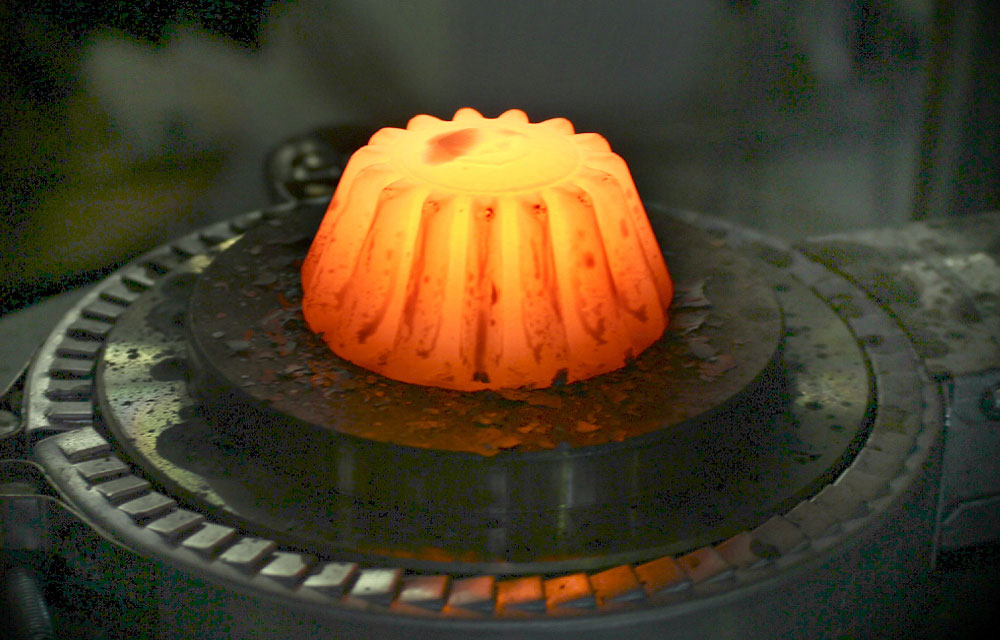

IFUM | For a more comprehensive determination of material properties: At the Institute of Forming Technology and Machines (IFUM), the Gleeble system has been installed at the Department Material Characterisation and Simulation. It is even suitable for simulating bulk metal forming processes.

- Research, Uncategorized

IPH | In future, factory layouts can be created a lot faster and at a more favourable price: On its flight across a factory, a UAV shall scan all the installations, storage areas and machines and create a three-dimensional model. This is one of the research topics of the Institut für Integrierte Produktion Hannover (IPH) gGmbH.

- Research

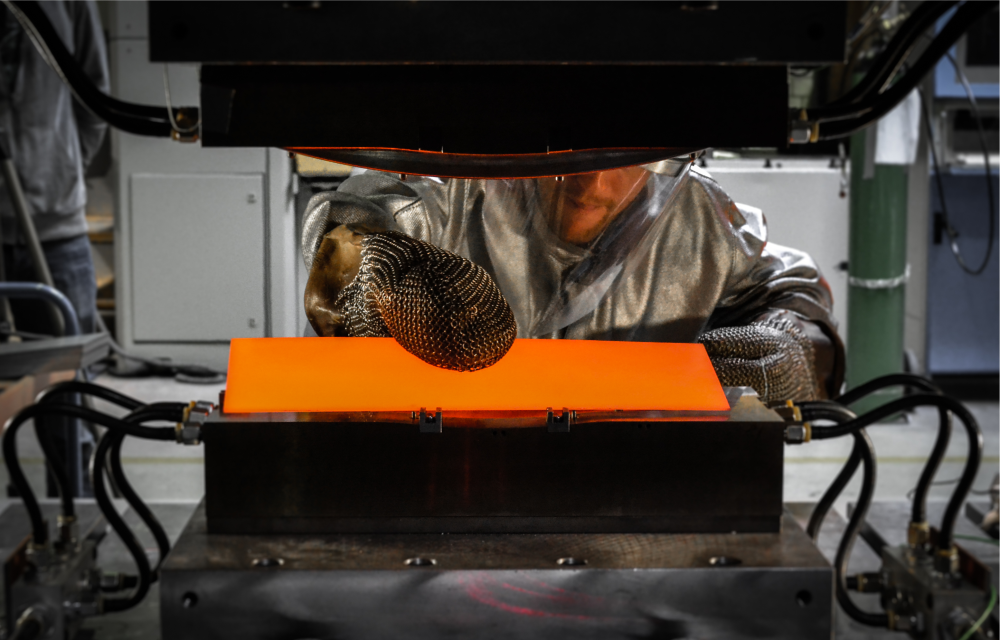

IFUM/IMPT | Precise temperature control is a decisive factor during hot stamping: Only if the component part is cooled down fast enough, it is hardened sufficiently. For direct temperature measurement in the tool, researchers at IFUM and IMPT developed a thin-film sensor.

- Here & now

CRC 1153 | Experts from the Collaborative Research Centre “Tailored Forming“ are developing new methods for the production of hybrid components, combining the advantages of different materials. Around forty technical exhibits will be presented at Hannover Messe taking place from 23 to 27 April.